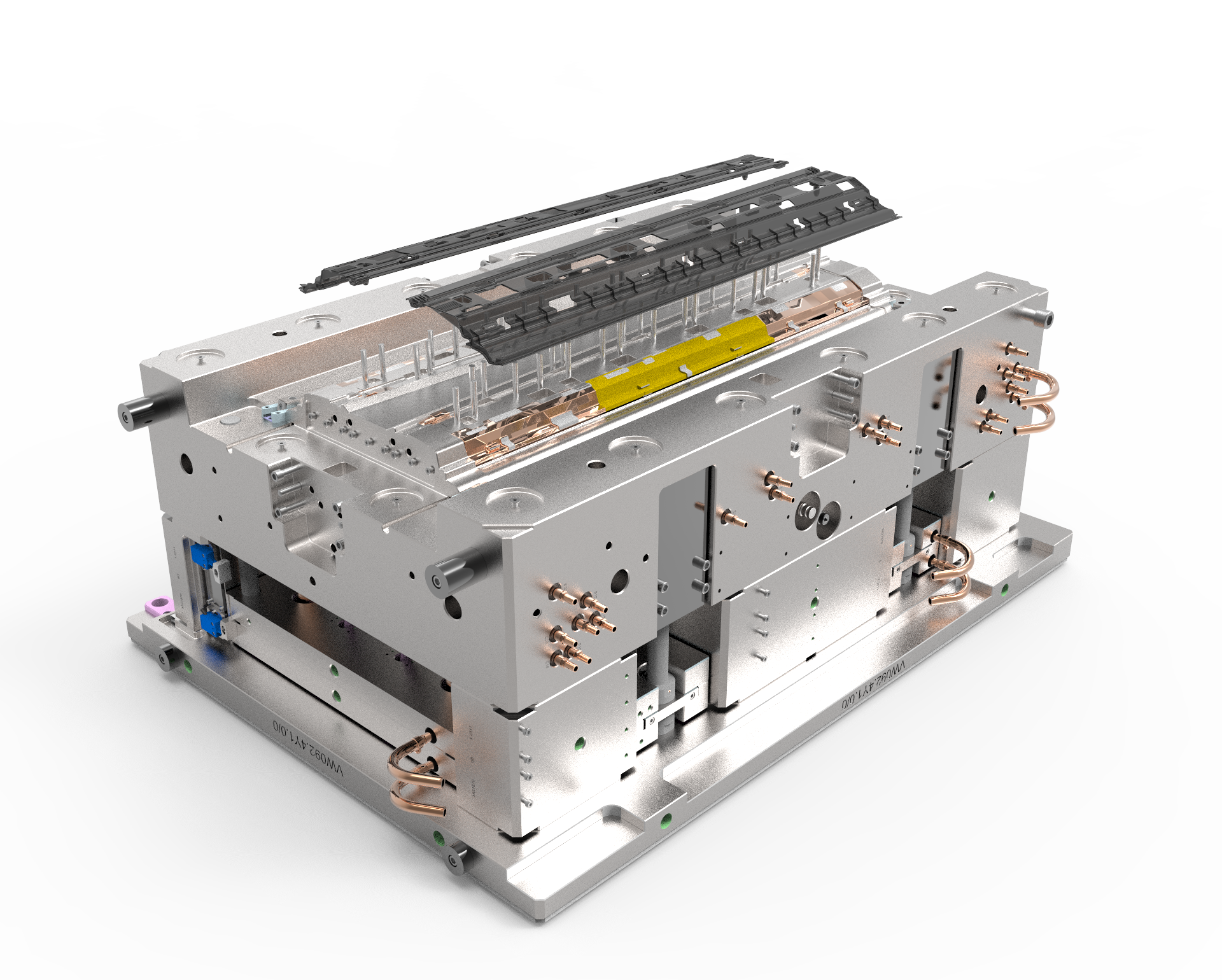

Industrial robotics molds require high precision for robotic arm components and sensor housings. We use titanium alloy inserts for lightweight, high-strength parts and implement multi-slide molds for complex geometries. These molds withstand continuous operation in harsh industrial environments.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy