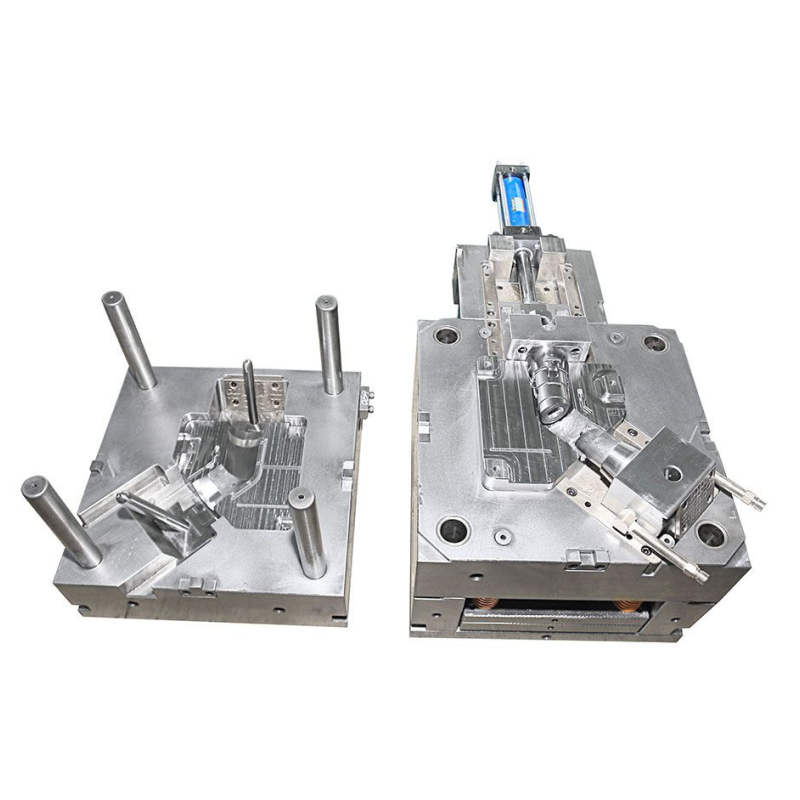

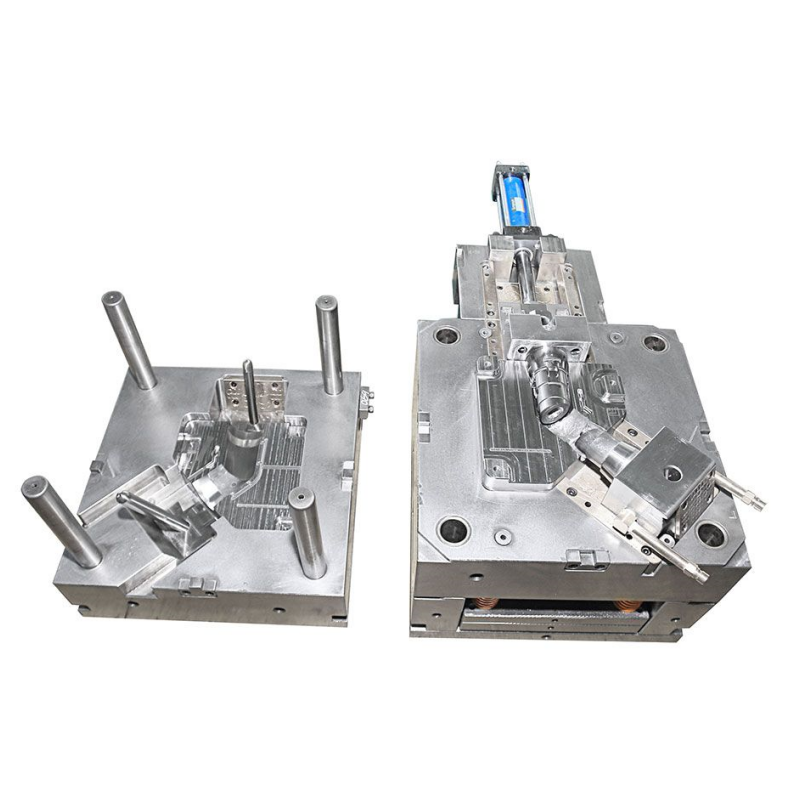

Pioneering plastic molds used in communication systems clearly define the modern telecommunications expectations. Out of the trend of technology, molds are made for various activities related to mobile phones, networking tools and consumer electronics. Using our injection molding expertise, we also know how to make the components work and look good and enhance the appearance of the communication device. We focus on quality and efficiency which makes us an attractive subcontractor to companies that seek to improve their range of products in the competitive globe.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy