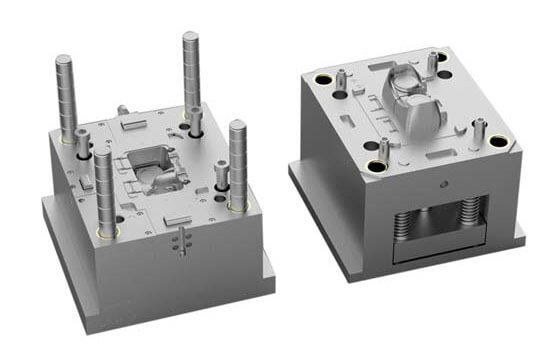

As per the industry requirements of our clients, our custom injection molds designing services are specially developed by Qingdao KAILY Electronic Technology Co., Ltd in China. There is an emphasis in developing the molds that make sure the dimensions of your products are accurate, and that speed up the injection molding procedure. An assortment of experienced engineers from within our firm collaborates directly with every client to shape their ideas so that they will be realized in the end product. If it’s about molding a car part, a part of household appliances, or an electronic component, we will always have an answer without sacrificing efficiency and the budget.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy