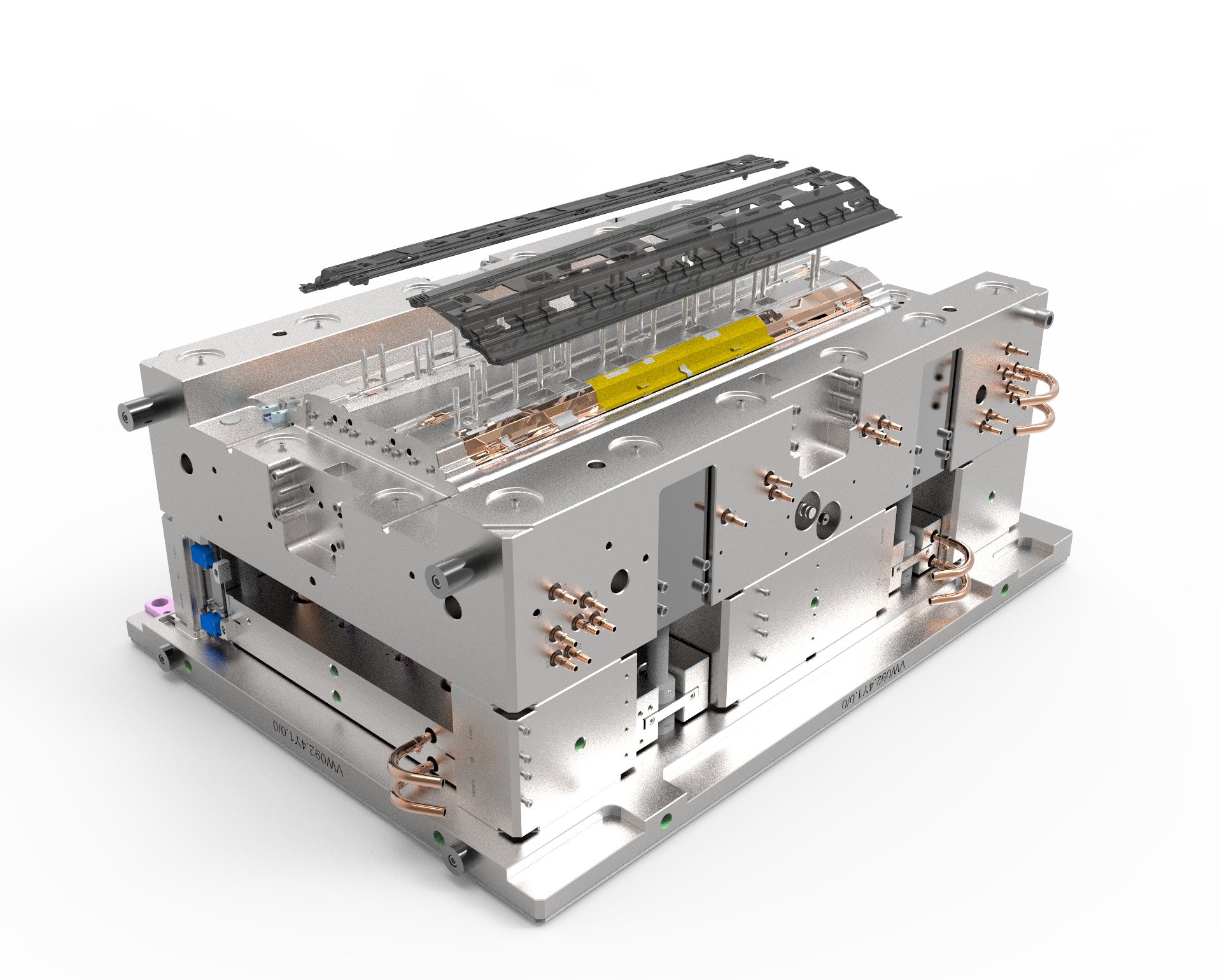

As a leading custom mold manufacturer, we offer end-to-end solutions from design to delivery, supporting diverse industries with low-volume prototypes to high-volume production molds. Our team specializes in complex geometries (overmolding, insert molding) and provides value-added services like surface finishing, assembly, and packaging, all backed by 20+ years of engineering expertise.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy