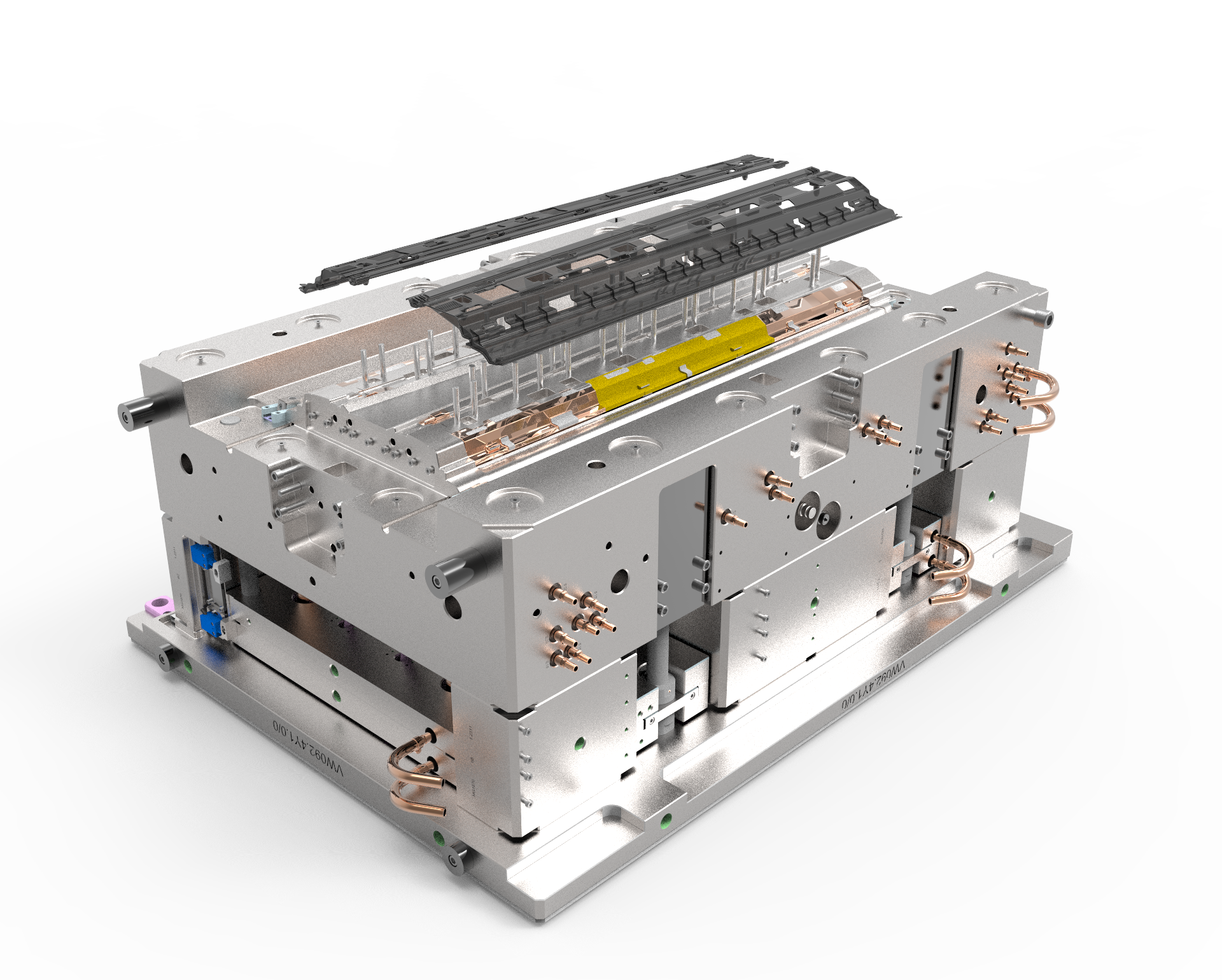

Our automotive mold production process reduces lead times via lean manufacturing. Automated material handling, parallel mold machining, and rapid prototyping (3D printing of mold inserts) cut production cycles by 40%. Real-time monitoring ensures consistent part quality across batches.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy