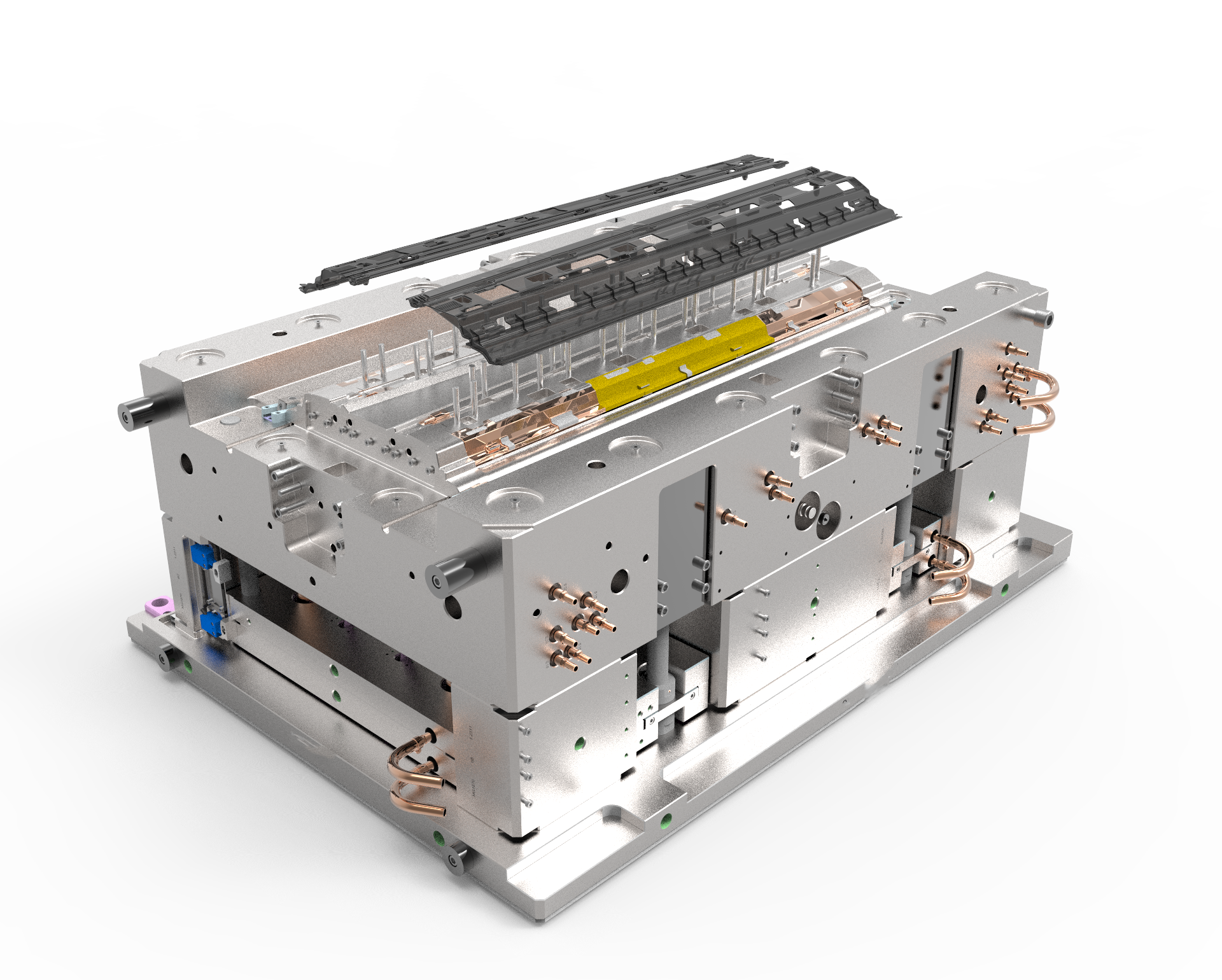

Our target markets are the automotive industries that require sturdy and high quality performance plastic molds. We recognize the requirements of automotive parts, where performance and accuracy are critical. Cutting-edge technology is utilized to manufacture our molds to ensure their appropriateness for automotive usage while preserving dimensional tolerance. We constantly seek new ideas and improvements for the processes, so we can fit the changing requirements of the automotive market and offer the best options to our customers.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy