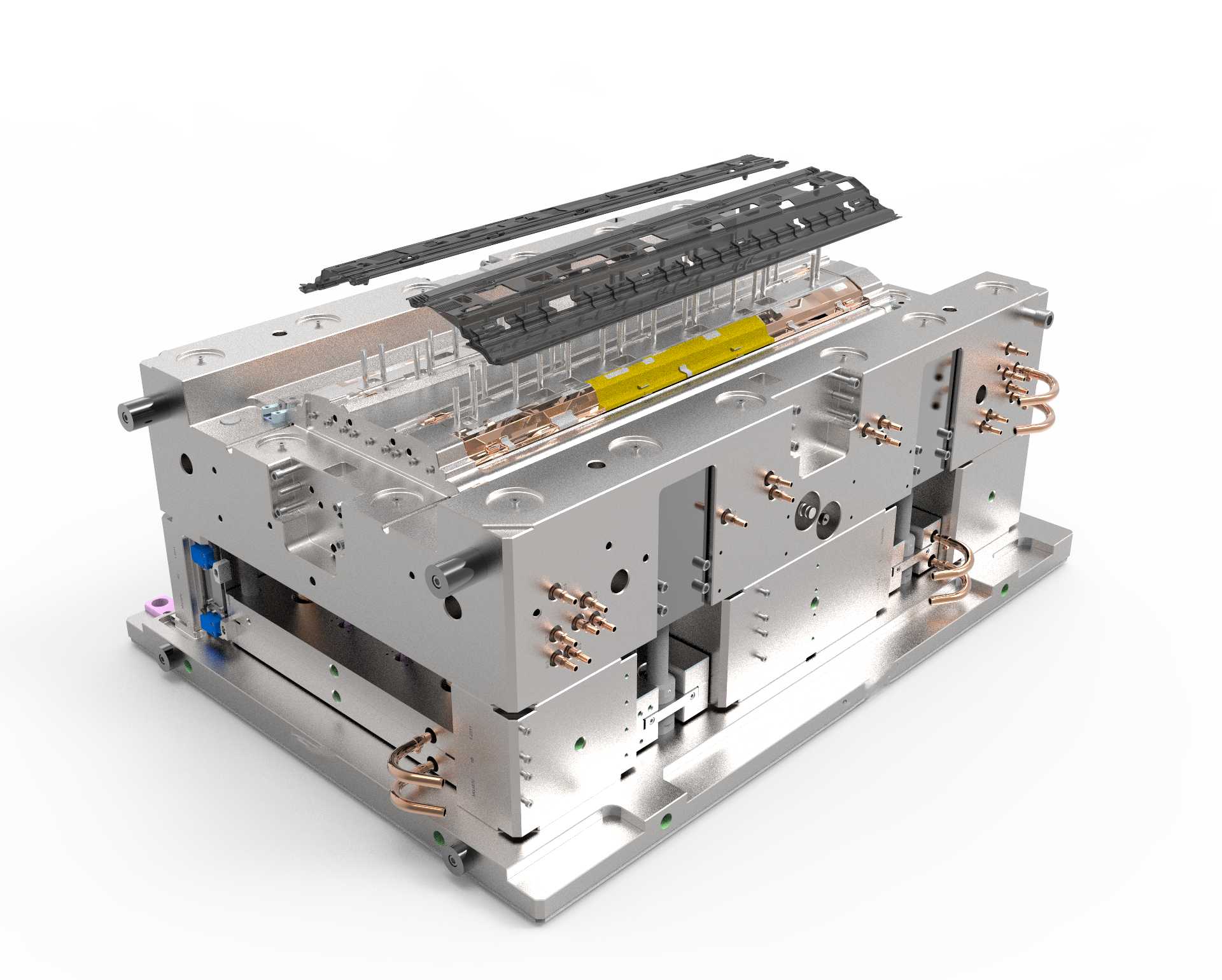

High-quality electronic accessory molds prioritize precision and surface finish. We use mirror-polished steel for glossy components and LSR (liquid silicone rubber) molds for flexible parts. Anti-oxidation treatments prevent corrosion in humid environments, ideal for outdoor electronics.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy