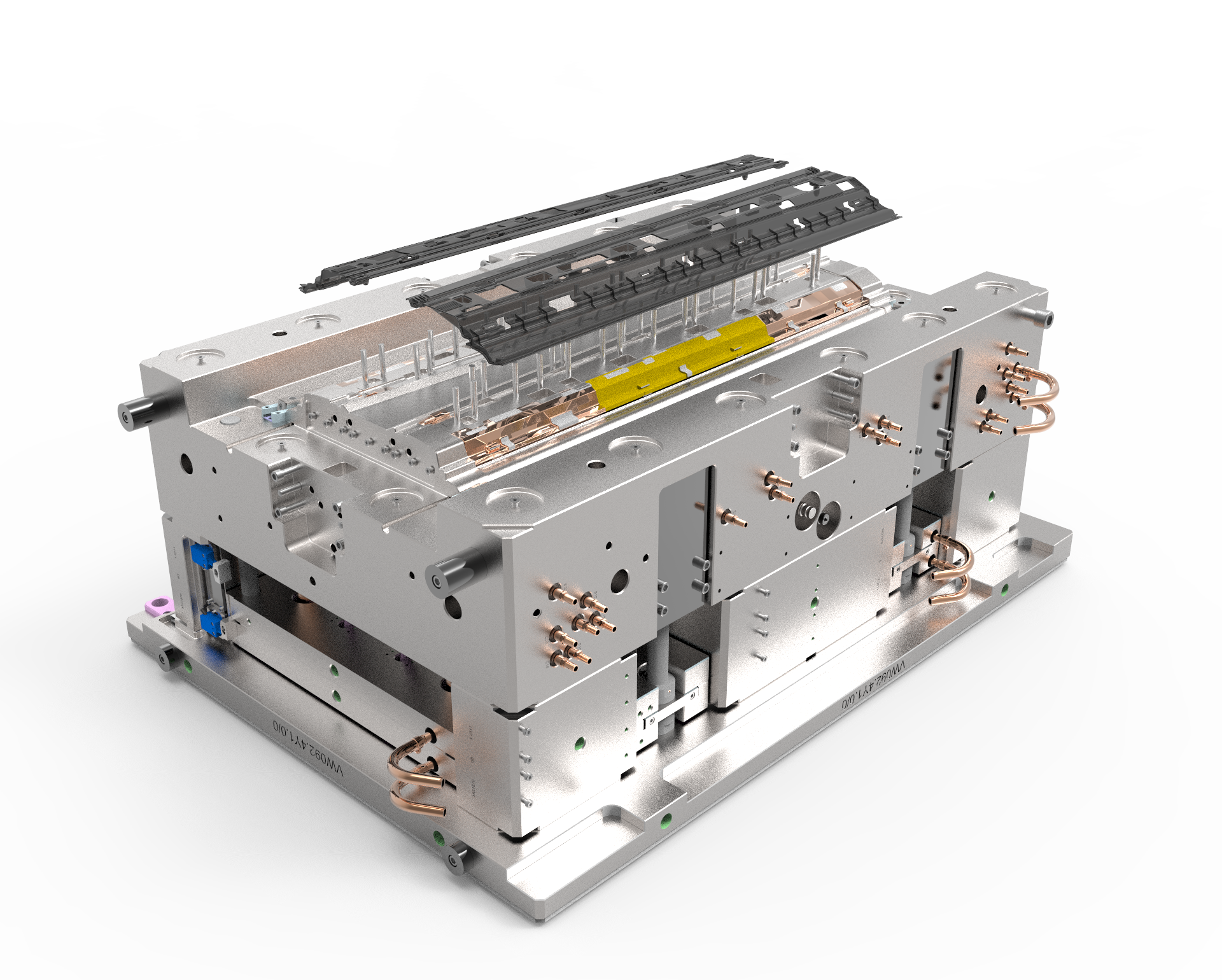

High-quality manufacturing is driven by our state-of-the-art facility, equipped with CNC machining centers, EDM machines, and robotic assembly lines. We strictly control material sourcing (certified steel suppliers) and implement heat treatment processes to enhance mold hardness and wear resistance. Every mold undergoes functional testing (mold flow, pressure resistance) before delivery.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy