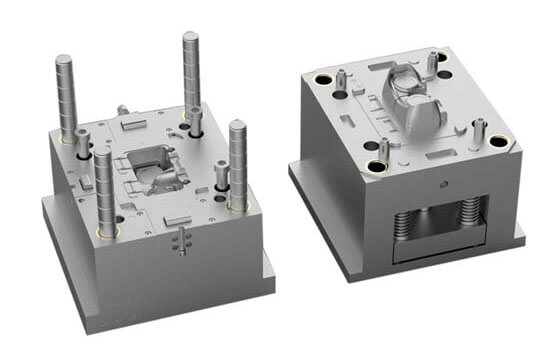

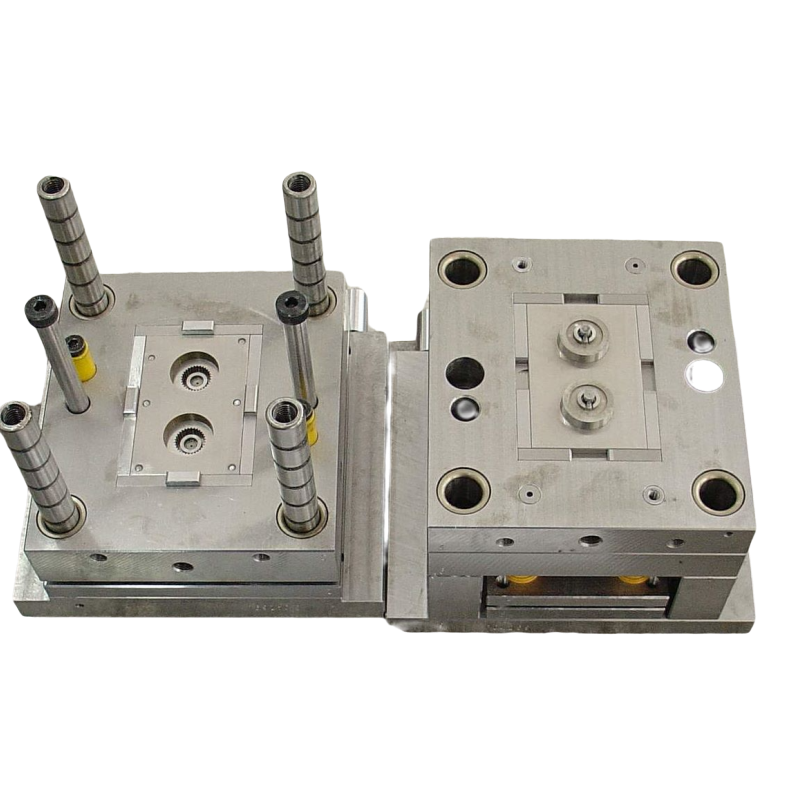

Qingdao KAILY Electronic Technology Co., Ltd. is focused on the production of high quality plastic moulds and plastics for electronic devices and household appliances. The molds are manufactured with a high degree of reliability and are shaped using methods of Injection molding which is needed for mass production of high-quality products. We practice the most advanced injection molding methods and operations for manufacturing HVAC units, telecommunications systems and appliances, and automotive electronics components. Our clients are confident in the quality of their products and always have high expectations.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy