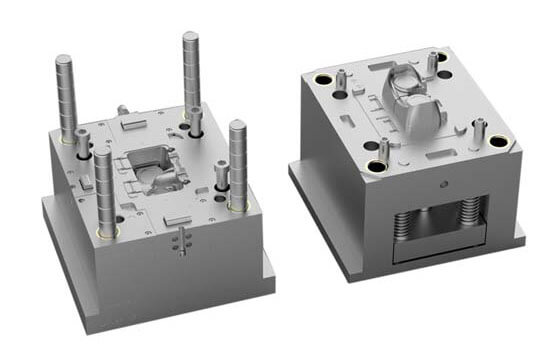

Household appliance molds focus on durability and user-friendly design, producing parts for kitchen tools, vacuum cleaners, and small appliances. We use flame-retardant materials for safety, textured surfaces for non-slip grips, and modular molds for easy product line switching. Our solutions balance cost-effectiveness with high-quality finishes, suitable for both premium and mass-market appliances.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy