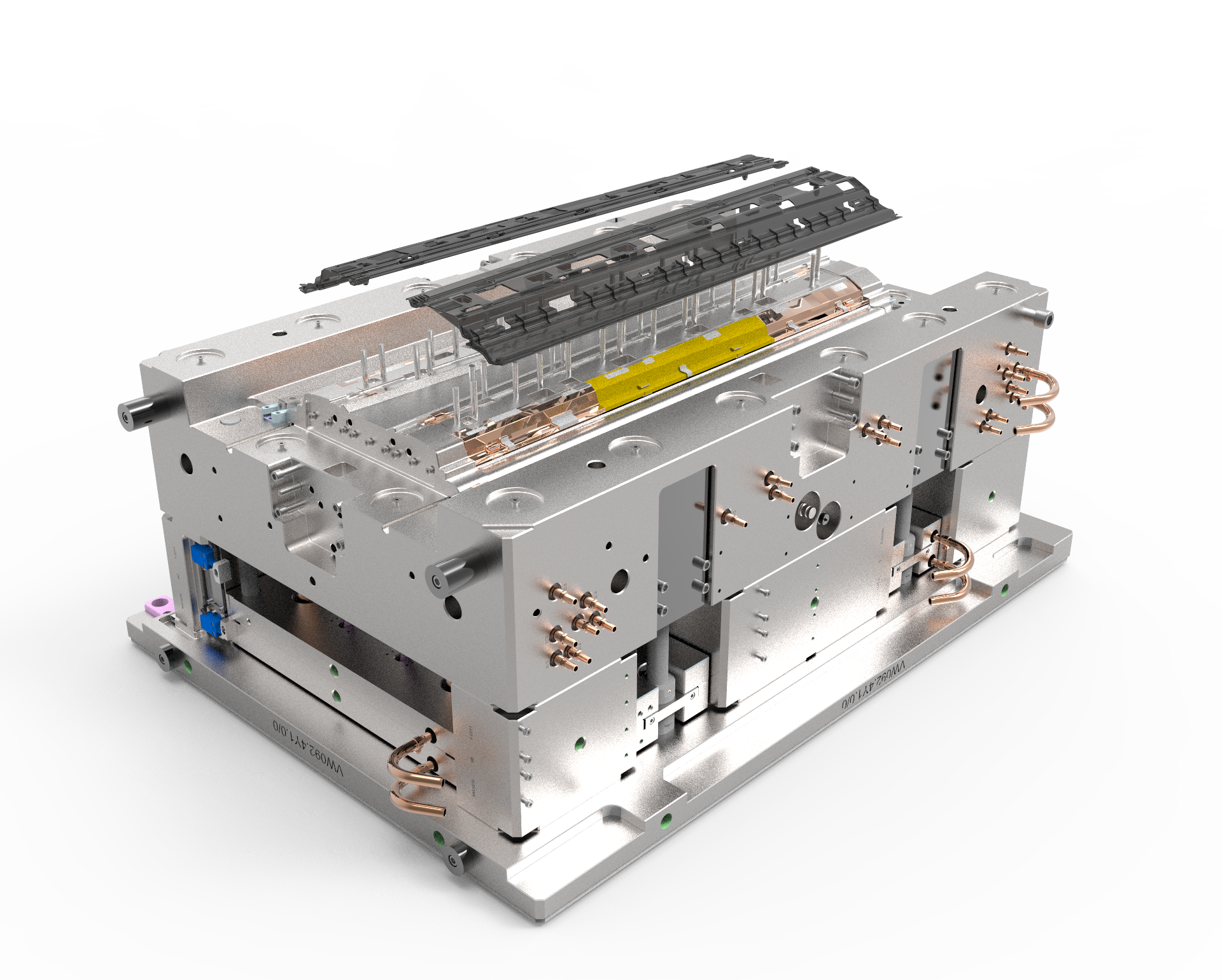

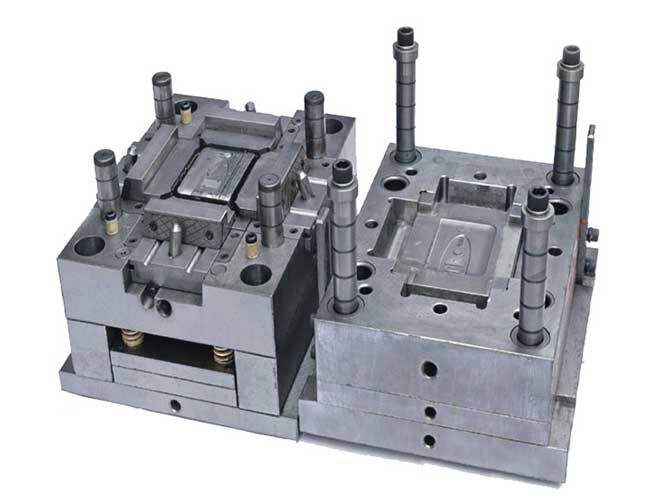

Manufacturing of an injection mold is an advanced process that includes prototyping of intricate molds for products especially thermoplastic. It commences with the development stage, where the designers in this case our team uses CAD software to make the design. Once the design outline has been drawn, we move into the construction of the actual mold or its parts, which consists of cutting, polishing and dynamic assembly of different details. The completed mold then focuses its properties ensuring it can withstand vigorous activities. The last procedure is the injection molding itself where the void is filled with liquid plastic to obtain the desired shape. We ensure that all our products are manufactured and sold in compliance with the industry standards.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy