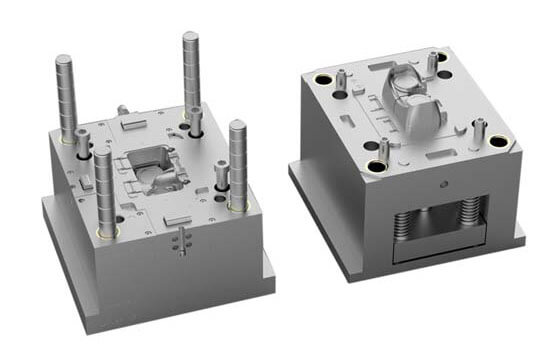

When comparing injection molds and thermoforming molds, Qingdao Kaily emphasizes the distinct advantages of injection molding for complex, high - precision applications. Injection molds offer superior dimensional accuracy (often within ±0.05mm), making them ideal for electronics, automotive parts, and medical devices where tight tolerances are critical. The process allows for multi - cavity designs, enabling high - volume production with minimal part variation. In contrast, thermoforming molds are better suited for simpler, larger parts like packaging trays, as they involve heating and stretching plastic sheets over a mold, which limits detail and precision. Kaily’s injection molds feature advanced components like hot runner systems to reduce material waste and conformal cooling to minimize cycle times—advantages not typically found in thermoforming. While thermoforming may be cheaper for low - volume runs, injection molding offers long - term cost savings through higher production speeds and material efficiency, making it the preferred choice for Kaily’s clients in industries demanding quality and repeatability.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy