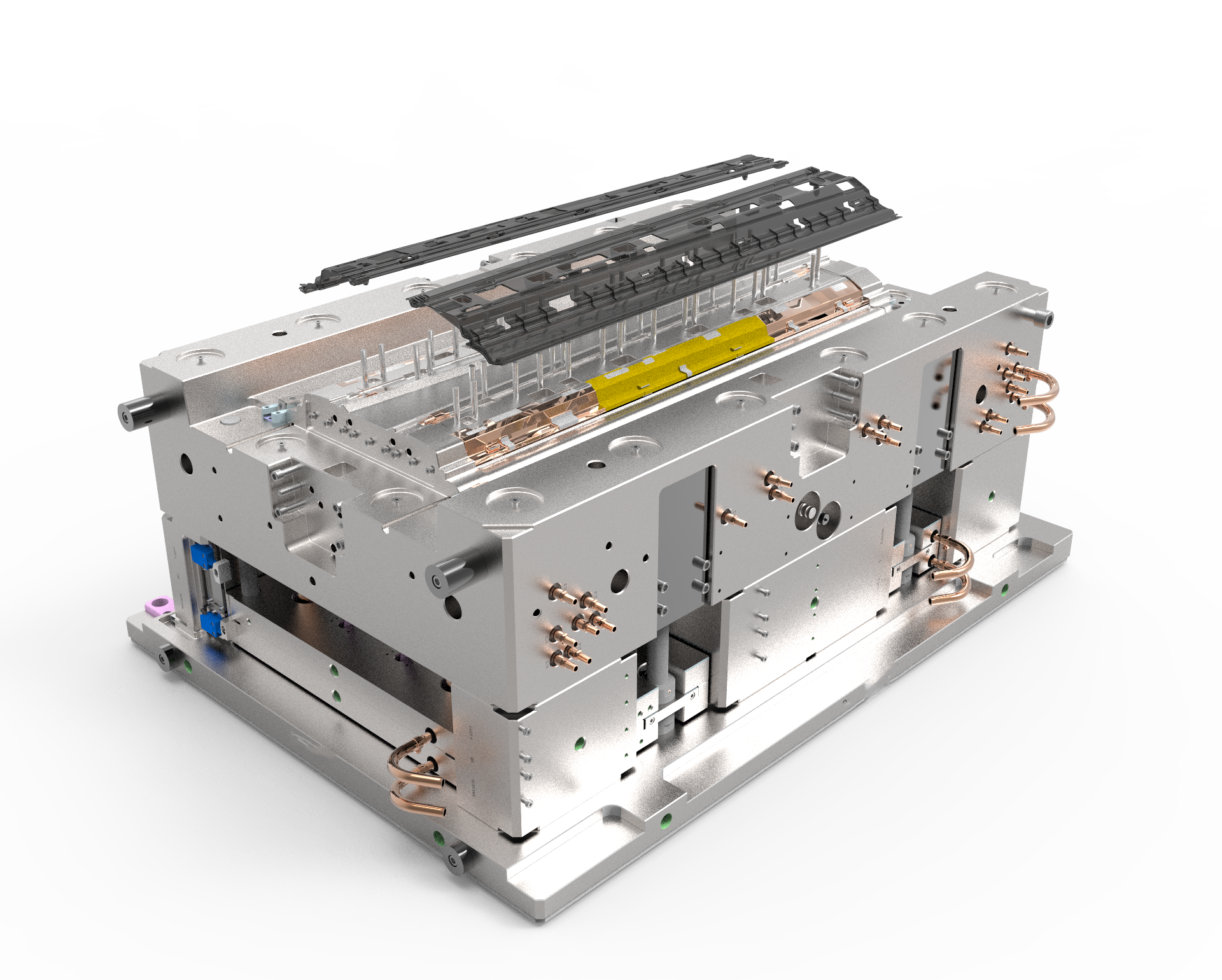

Plastic Mold Design and Funnel Design Other Engineering Services Available.

Thank you for taking the time to stop by the website of Qingdao KAILY Electronic Technology Co., Ltd. We are glad you found our company. Rest assured that you will receive the best plastic mold designing and making services from our firm. Our firm was founded in the year 2010 and in recent times it has gained status as a national high-tech company. With significant investment, the firm is involved in offering end to end manufacturing services for injection molding components for various industries such as automotive, white goods, electrical appliances, stationary products and many more. The firm has invested a total amount of $15 million and owns a factory area of 50,000 square meters which allows it to maintain high standards of mold design, injects molding, and several others such as assembly, spraying and vacuum plating. Our products are in high demands around the globe including North America, Japan, South America and South East Asia.

Get A Quote

ONLINE

ONLINE