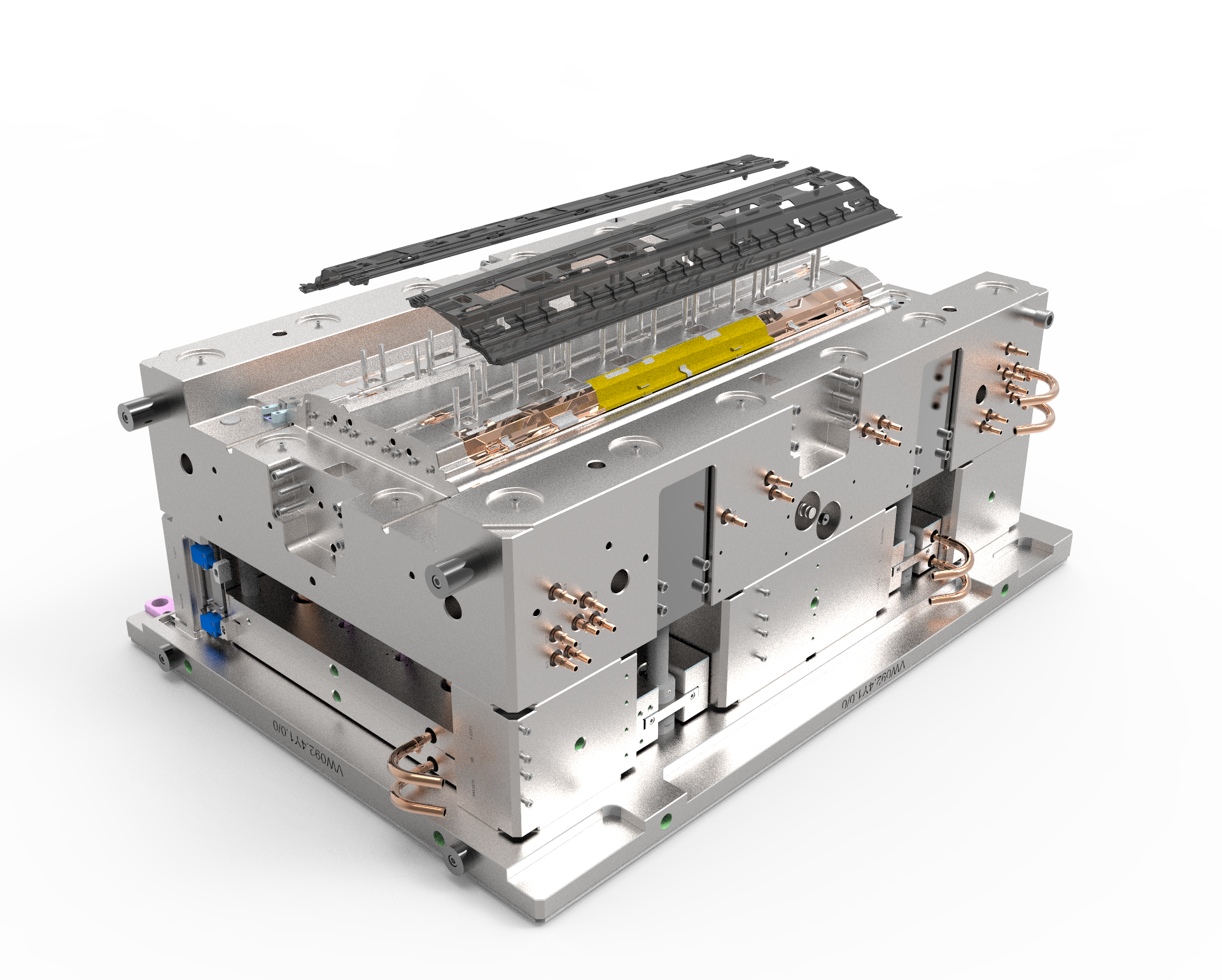

Our plastic mold for audio equipment improves sound quality while also being aesthetically pleasing to the users. As the radio industry is quite diverse, quality and usability are also prioritized with the help of our focused molds. We use high quality and advanced injection molding methods which ensure that the production quality is consistent and waste is minimized as much as possible. Our team values the audio equipment need to detailed instructions hence we deliver molds that exceed your expectations.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy