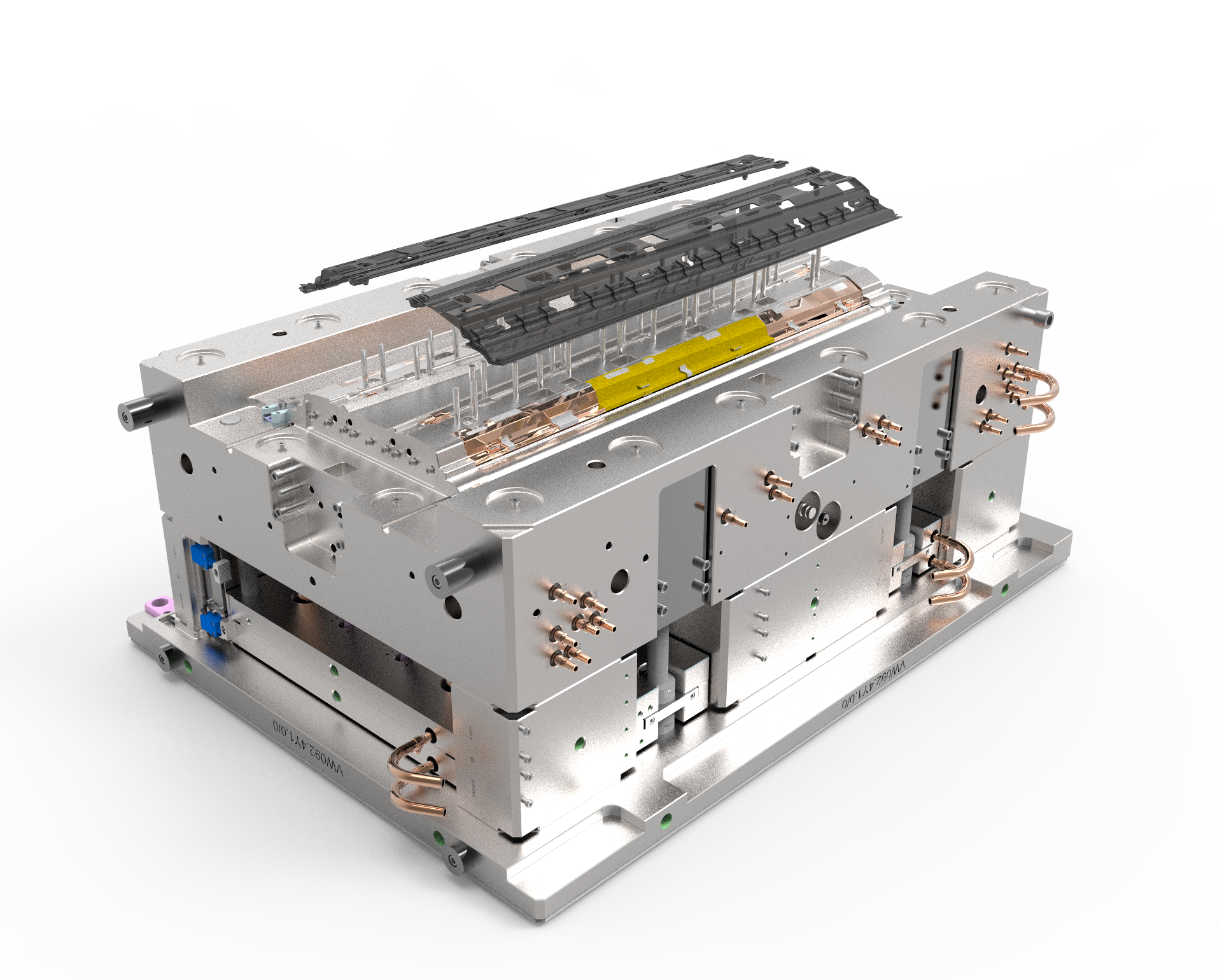

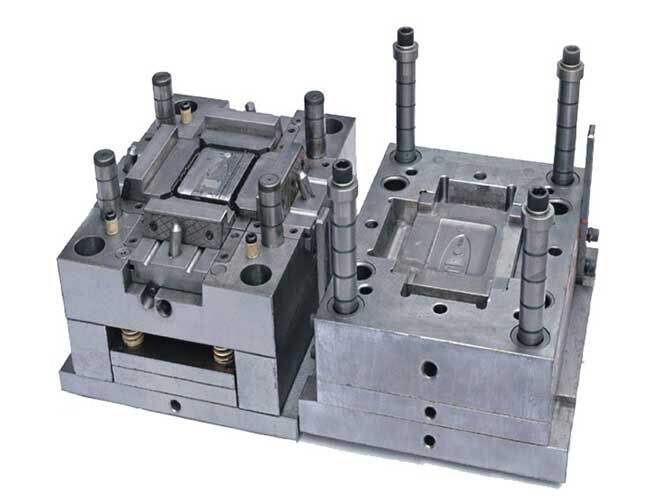

Компанията Qingdao Kaily Electronic Technology Co., Ltd. предлага всеобхватни услуги за производство на инжекционни форми. От първоначалния концепт до крайната доставка на формата, firmaта предоставя решения от начало до края. Нейните услуги включват проектиране на форми, при което екип от изкуствени инженери използва moden 3D проектен софтуер и симулационни инструменти, за да създадат форми, които отговарят на продуктните изисквания на клиента. Процесът на производство включва използването на най-новото оборудване, като CNC фрезировачни центрове, машини за електрохимично раздробяване (EDM) и фрезировачни машини, за да се изработят формовните компоненти с висока прецизност. Качеството е интегрирана част от услугите за производство, с строги проверки, провеждани на всеки етап от производството, за да се гарантира, че формите отговарят на необходимите стандарти. Предоставя се и поддръжка след продажбата, включително обслужване, ремонтни услуги и техническа помощ за формите. Способността на компанията да предлагат персонализирани решения, бързи срокове за изпълнение и конкурентни цени прави нейните услуги за производство на инжекционни форми много привлекателни за клиенти от различни индустрии. Дали е маломасштабен проект или голям обем на производство, Qingdao Kaily разполага с необходимата експертиза и ресурси, за да доставя висококачествени инжекционни форми, които отговарят на очакванията на клиента.

НА ЖИВО

НА ЖИВО

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Политика за поверителност