The Fundamentals of Automotive Injection Molding

Defining Plastic Injection Molding

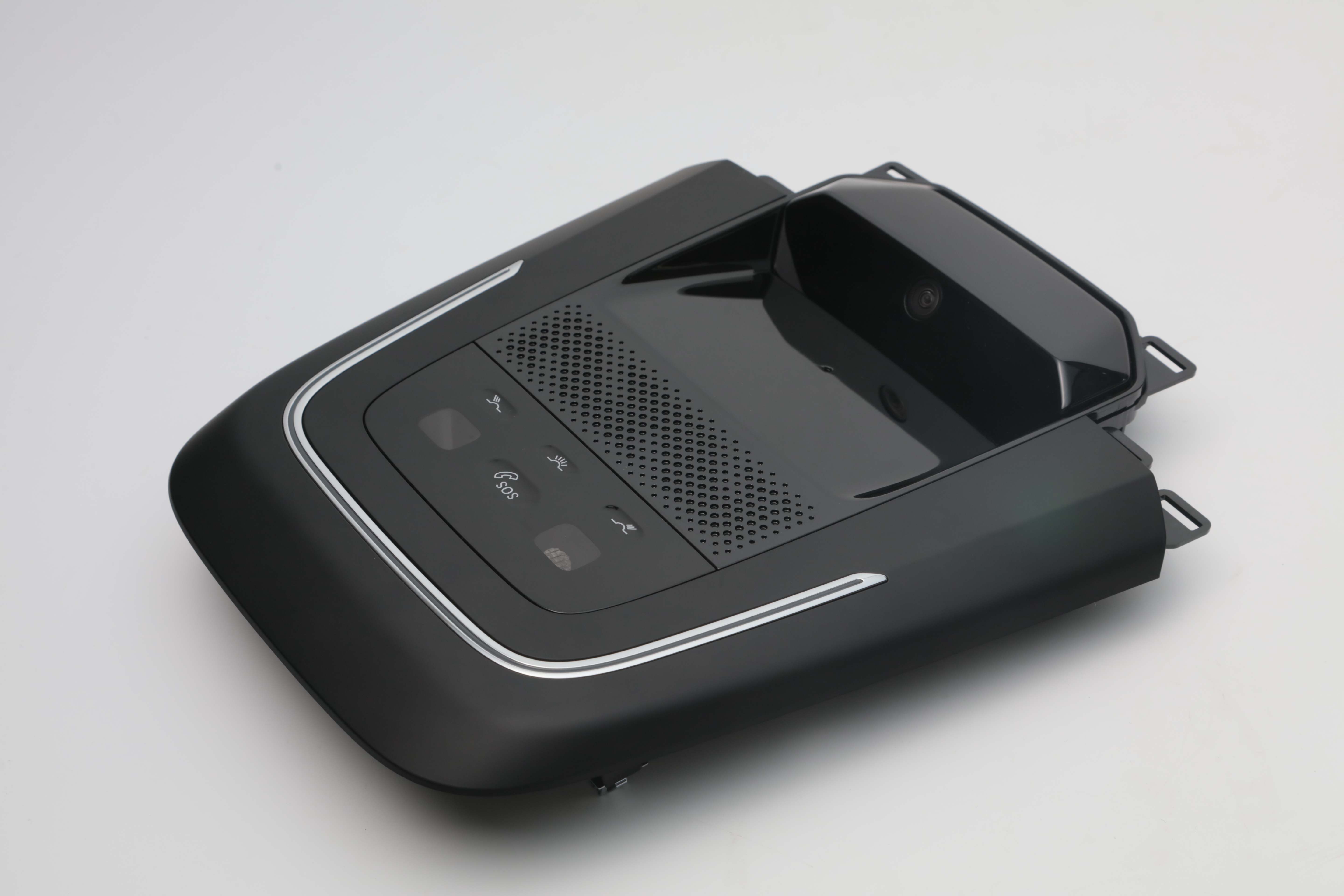

Plastic injection molding is a crucial process in the manufacturing of automotive components. It involves injecting molten plastic into a specially designed mold to shape products precisely according to specifications. This method is favored due to its efficiency and the ability to produce consistent parts. Common materials used in automotive injection molding include ABS, polypropylene, and nylon, each offering specific benefits in terms of durability and weight. Precision in automotive injection molding is paramount, as the industry demands exact tolerances for components to ensure they fit seamlessly within complex assemblies. The capability to meet these stringent requirements highlights plastic injection molding's importance in automotive manufacturing.

Key Advantages for Automotive Applications

Injection molding offers several key benefits for automotive applications, making it a preferred choice in this sector. First and foremost, it delivers high production efficiency and is cost-effective, attributes critical for large-scale manufacturing. With the capability to produce thousands of parts per hour, the production speed is unmatched, supporting rapid assembly processes within the automotive industry. Furthermore, injection molding allows for the creation of complex geometries and intricate designs, which are essential for modern automotive components. This flexibility enables manufacturers to meet consumer demands for innovative and aesthetically pleasing vehicle features while maintaining strict functional standards. These advantages underline the strategic importance of injection molding in automotive manufacturing.

From Design to Production: The Injection Molding Workflow

Conceptual Design Phase for Auto Parts

The conceptual design phase marks the beginning of creating automotive parts via injection molding. Initially, this involves ideation and sketching, where design concepts are brainstormed and visualized. Computer-Aided Design (CAD) software plays a critical role in this phase as it allows for detailed designs and precise specifications to be developed. A key aspect of this phase is the collaboration between engineers and designers. Such cooperation ensures that the designs are manufacturable and comply with necessary specifications, thereby laying a solid foundation for the subsequent stages in the injection molding process.

Mold Creation and Testing

Creating and testing molds is a crucial step in the injection molding process. Mold creation begins with selecting appropriate materials that withstand repeated use and high-pressure conditions. Mold fabrication techniques, such as CNC machining and electrical discharge machining, are used to shape the mold. Additionally, the integration of cooling channels in the mold structure ensures efficient temperature control during production. Rigorous testing procedures follow, where molds undergo trial runs to validate their performance. Adjustments to parameters, based on these trials, help optimize both quality and efficiency, ensuring that the final mold consistently produces high-quality parts.

Mass Production Techniques

Mass production in injection molding harnesses advanced techniques to maximize efficiency. Multi-cavity molds are often used, allowing multiple parts to be produced in a single cycle, thereby increasing output dramatically. Automation also plays a significant role, with robotic systems handling tasks such as part removal and inspection, minimizing human error and labor costs. Modern injection molding machinery, equipped with precise control systems, further enhances production speed and consistency. For automotive injection molding, these techniques enable rapid production cycles, ensuring parts are manufactured at scale while maintaining stringent quality standards.

Injection Molding vs. 3D Printing in Auto Part Manufacturing

Cost-Efficiency Comparison

In comparing the cost-efficiency of injection molding versus 3D printing for the manufacturing of auto parts, we find distinct advantages depending on the production scale. Injection molding excels in large production runs due to its ability to produce high volumes at reduced costs per unit. For instance, it is widely cited in industry reports that beyond a certain threshold, typically around 1000 units, the fixed costs associated with mold creation are outweighed by the economies of scale achieved. Conversely, 3D printing shines in small batch productions or for creating prototypes, where the absence of tooling costs allows for flexibility and cost savings. This makes 3D printing highly suitable for custom parts or limited-run applications.

Material Limitations and Strengths

When evaluating the materials used in injection molding versus 3D printing, both offer unique strengths and limitations. Injection molding supports a wide variety of materials like polypropylene and ABS, which provide excellent durability and heat resistance—ideal for automotive parts such as bumpers and dashboard components. In contrast, 3D printing primarily uses materials like PLA and ABS filament, which are limited in heat resistance and mechanical strength compared to injection-molded parts. However, 3D printing’s ability to rapidly iterate designs allows for material experimentation and is suited for creating intricate shapes that are impractical with traditional methods. Therefore, selecting the appropriate method depends on the specific material needs and functionalities required for each automotive application.

Quality Assurance in Automotive Injection Molding

Testing Protocols for Durability

In the realm of automotive injection molding, ensuring the durability of each component is paramount. Rigorous testing protocols are established to scrutinize these parts under various environmental and stress conditions. For instance, components often undergo thermal cycling and mechanical stress tests to simulate real-world conditions. Standards organizations like ASTM and ISO play a crucial role by setting benchmarks for these tests, enabling manufacturers to align their products with industry-wide excellence standards. Adhering to such protocols not only guarantees product longevity but also bolsters consumer confidence in the reliability of automotive parts molded from plastics.

Meeting Automotive Industry Standards

Compliance with industry standards is a critical facet of producing injection molded automotive parts. These standards, encompassing safety, performance, and durability metrics, are imperative for ensuring the components meet the rigorous demands of automotive applications. For instance, adherence to standards set by ISO or SAE ensures that parts can withstand road hazards and perform under extreme conditions. Failing to meet these criteria can result in significant legal and marketability challenges, emphasizing the vital role of compliance in maintaining a competitive edge. Ensuring parts meet these standards not only facilitates legal conformity but also enhances the market acceptability of the products.

Innovations Shaping the Future of Auto Part Manufacturing

Advanced Materials for Lightweighting

The automotive industry is rapidly adapting to advanced materials aimed at lightweighting, with innovations such as composite materials and advanced polymers. These materials are revolutionary because they significantly reduce the weight of vehicles, improving fuel efficiency and performance. According to industry statistics, reducing a vehicle's weight by 10% can improve fuel economy by 6% to 8%. This shift not only enhances vehicle performance but also aligns with global sustainability goals by reducing carbon emissions. Lightweight materials, therefore, play a critical role in the next generation of vehicle manufacturing, leveraging the power of automotive injection molding for efficient and streamlined production.

Smart Manufacturing Integration

Smart manufacturing technologies, such as IoT and data analytics, are increasingly pivotal in optimizing the injection molding process for automotive parts. These technologies streamline production by improving efficiency, reducing waste, and ensuring top-notch product quality. For instance, data from a recent study indicates that integrating IoT can lead to a 15% increase in production efficiency through real-time monitoring and predictive maintenance. Additionally, case studies have highlighted how smart manufacturing leads to a significant reduction in waste by analyzing production data to minimize defects. By harnessing these technologies, manufacturers can enhance the efficiency of plastic injection molds for stationery and other automotive uses, staying at the forefront of innovation in automotive injection molding.

ONLINE

ONLINE