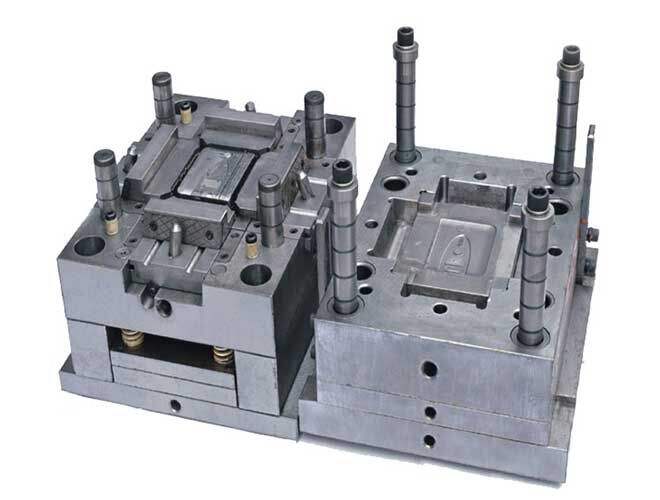

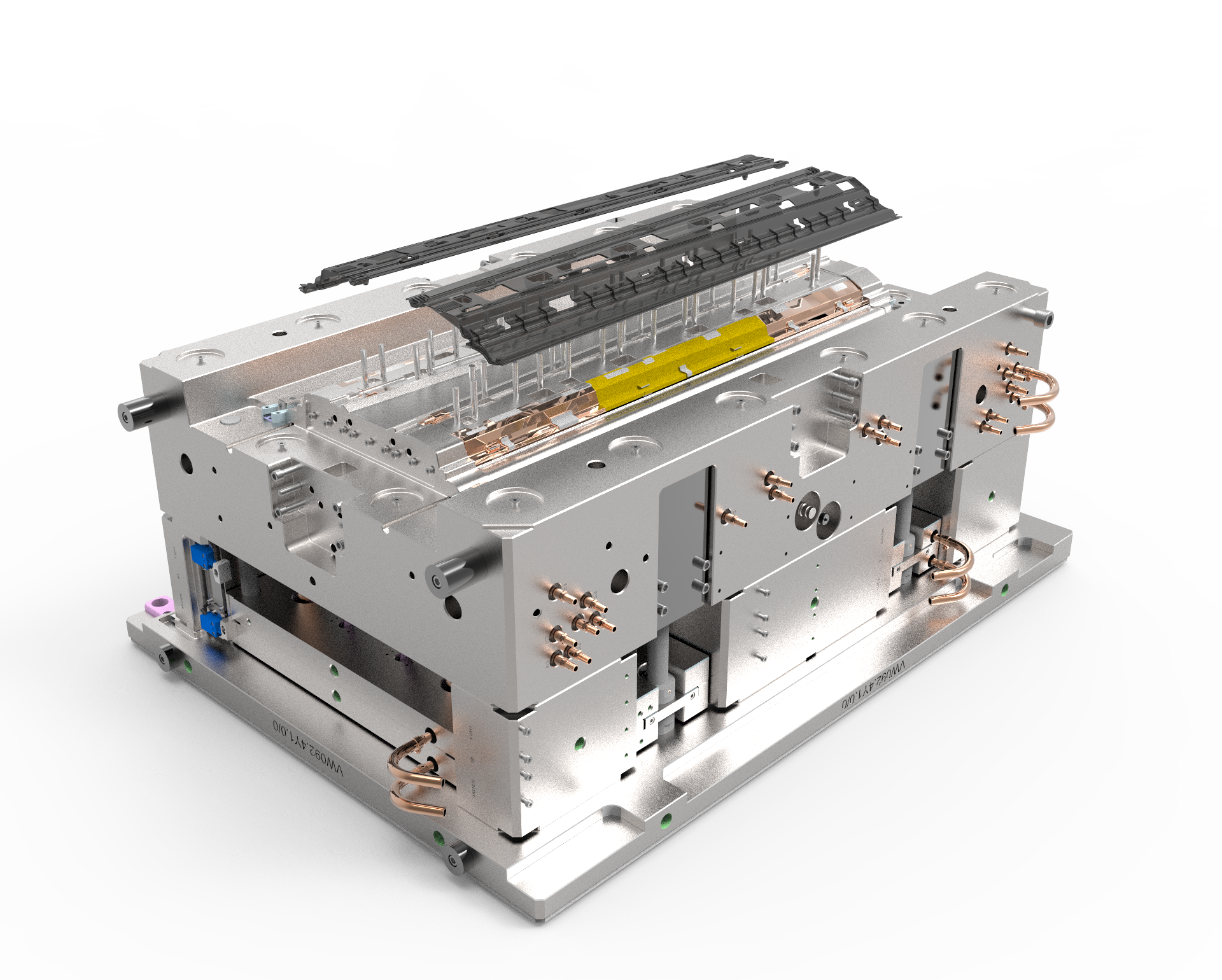

Η Qingdao Kaily διαχωρίζει τα ηλεκτρονικά και γραφικά εισαγωγικά μούλδινγκ προσαρμόζοντας σχεδιασμούς στις ειδικές απαιτήσεις κάθε βιομηχανίας. Τα ηλεκτρονικά εισαγωγικά μούλδινγκ επικεντρώνονται στην ακρίβεια και τη μικροποιϊκή, με συχνότητα να περιλαμβάνουν μικροεισαγωγικά, επιφάνειες υψηλής λάμψης και στενές υπολήπτες (π.χ., ±0,02mm για τα καταδεξιμένα κεντρικά). Η εταιρεία χρησιμοποιεί ανθισταμένα σε διάβρωση μετάλλια εργαλείων και ενσωματώνει προστασία από ηλεκτροστατική αποπομπή (ESD) στις επιφάνειες των μούλδινγκ για να αποφεύγει ζημιές σε ευαίσθητα συστατικά. Οι διαύλους ψύξης σχεδιάζονται στρατηγικά για να αποφεύγουν την καμπύλωση σε μικρές τοιχώματα όπως τα κελύφη των κινητών τηλεφώνων. Αντιθέτως, τα γραφικά εισαγωγικά μούλδινγκ επικεντρώνονται στην κοστολογική αποδοτικότητα και την αισθητική έλξη. Η Kaily χρησιμοποιεί μετάλλια με χαμηλότερη σκληρότητα για εύκολη τριβοποίηση (π.χ., για φθειρωτά μοτίβα στα σώματα φοντών) και σχεδιάζει μούλδινγκ με γρήγορα-αλλαγή εισαγωγικών για να αντισταθεί σε παραλλαγές χρωμάτων. Οι θέσεις πύλων επιλέγονται για να κρύβουν τις συνδετικές γραμμές σε ορατές επιφάνειες, ενώ τα συστήματα εκβολής είναι επιεικείς για να διατηρούν περίπλοκα σχέδια σε αντικείμενα όπως κοσμημένα διαβήτρια. Και τα δύο τύποι μούλδινγκ επωφελούνται από τη μοντερνιστική προσέγγιση σχεδιασμού της Kaily, επιτρέποντας εύκολη προσαρμογή στις αλλαγές στις τάσεις προϊόντων.

ONLINE

ONLINE

Δικαιώματα πνευματικής ιδιοκτησίας © 2024 από την Qingdao KAILY Electronic Technology Co., Ltd. Πολιτική Απορρήτου