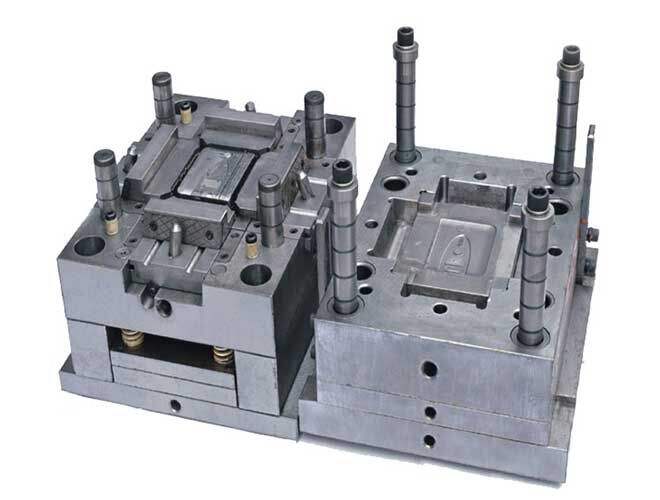

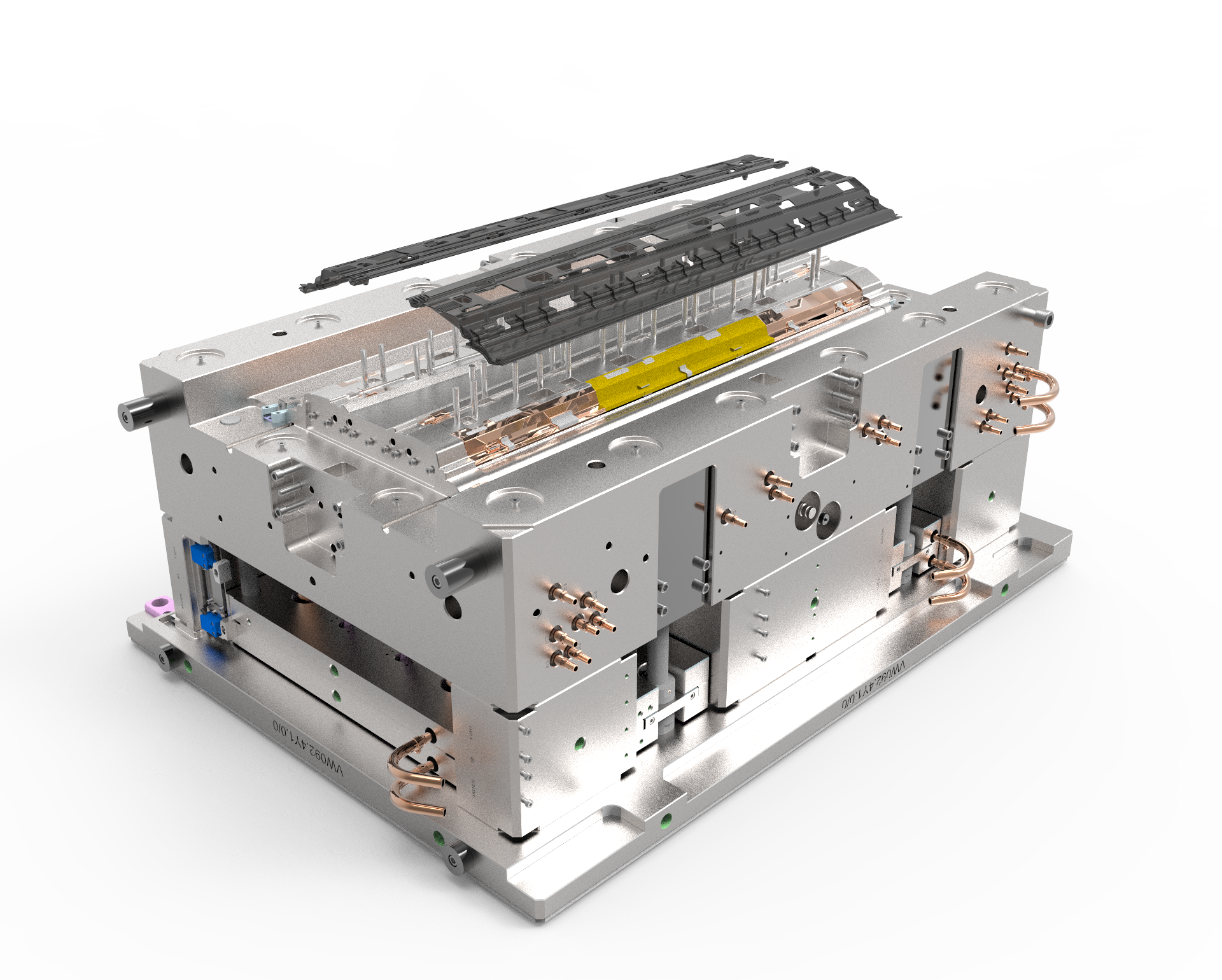

شاندائو کیلی تفاوت میان قالبهای تزریق الکترونیک و ادوات نوشتن را با طراحی سفارشی برای نیازهای منحصر به فرد هر صنعت ایجاد میکند. قالبهای تزریق الکترونیک دقت و کوچکسازی را در اولویت قرار میدهند و اغلب شامل درجات میکرو، سطوح با لمعان بالا و تحملهای بسته (مثلاً ±0.02mm برای جعبههای وصله) هستند. این شرکت از فولاد ابزار مقاوم به خوردگی استفاده میکند و حفاظت از بار الکترостاتیک (ESD) را در سطوح قالب برای جلوگیری از آسیب به مولفههای حساس اعمال میکند. کانالهای سرمایش به گونهای استراتژیک طراحی شدهاند تا پیچیدگی را در قطعات دیواره نازک مثل جعبههای تلفن همراه جلوگیری کنند. در مقابل، قالبهای تزریق ادوات نوشتن روی استحکام اقتصادی و جذابیت ظاهری تمرکز دارند. کیلی از فولادهای با سختی کمتر برای متن زدن آسانتر (مثل الگوهای گرفتگی روی بدنه گوشپیچ) استفاده میکند و قالبها را با درجات تغییر سریع قابلیت انتخاب رنگهای مختلف را دارا میکند. محلهای درجهگیری به گونهای بهینه شدهاند که خطوط جوش را روی سطوح قابل مشاهده مخفی کنند، در حالی که سیستمهای خروجی به گونهای نرم طراحی شدهاند تا طرحهای پیچیده روی اقلام مانند پیمانههای تزئینی را حفظ کنند. هر دو نوع قالب از رویکرد طراحی ماژولی کیلی بهره میبرند که امکان سازگاری آسان با روندهای تغییری محصولات را فراهم میکند.

آنلاین

آنلاین

کپیرایت © 2024 توسط شرکت فناوری الکترونیک کایلی قینگدائو. سیاست حریم خصوصی