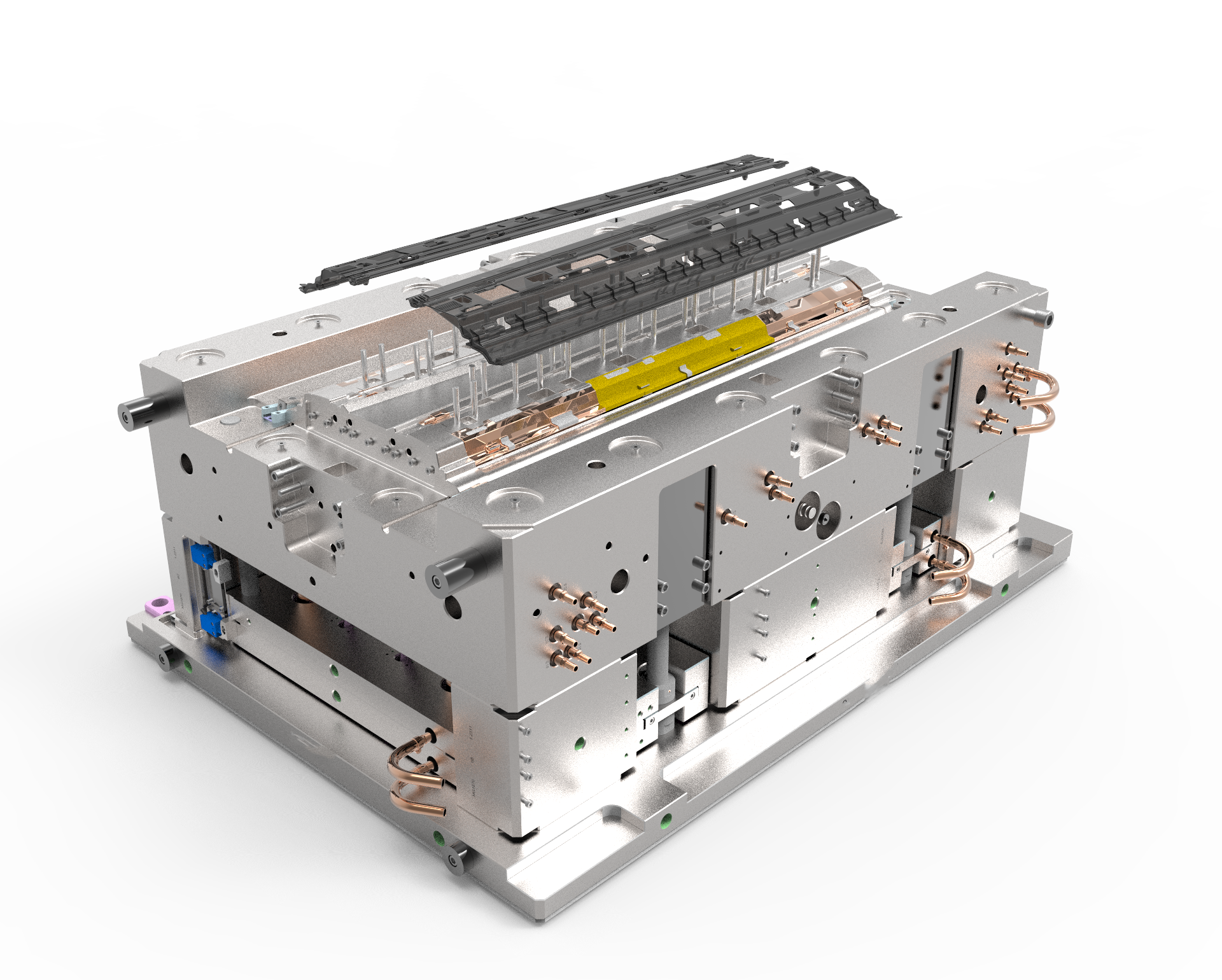

Qingdao Kailyn injektioformien valmistusprosessi on järjestelmällinen sekoitus teknistä osaamista ja edistyksellisiä tuotantoteknologieita. Matka alkaa yksityiskohtaisesta suunnittelukonsultoinnista, jossa insinöörit käyttävät CAD/CAM-ohjelmistoja muuntaakseen asiakkaiden vaatimukset 3D-muovailumuotoihin, ottaen mukaan virtausanalyysin ennustaa materiaalin käyttäytymistä. Seuraavaksi tarkkuusmecaanikkovaiheet hyödyntävät 5 - akselisia CNC-myllyjä ja särmäEDM-koneita muovailumuotojen komponenttien valmistamiseen sallimalla toleransseja ±0.01mm. Lämpökäsittelyprosesseja, kuten vakuumikuivatus- ja temperointimenetelmiä, sovelletaan parantaakseen materiaalin kovuutta ja kuljetuskestävyyttä. Montausta seuraa, kun teknikot integroitavat poistojarjestelmät, jäähdytyspiiritykset ja porttausmekanismit varmistaen tarkkan kohdistuksen. Jokainen muovailumuoto käy tiukassa testauksessa, mukaan lukien kokeilukierrokset arvioidakseen osan poistoa, pinnanpinta laatu sekä mittojen tarkkuus. Yrityksen ohutusvalmistuslähentämisen avulla vähennetään toimitusaikoja, kun taas omistettu laadunhallintajoukko varmistaa, että jokainen muovailumuoto täyttää kansainväliset standardit (esim. ISO 9001). Tämä alusta-loppu-prosessi korostaa Kailyn sitoutumista toimittamaan muovailumuotoja, jotka ovat kestäviä, tehokkaita ja tuottavat johdonmukaisesti.

VERKKOYHTEYDEN KAUTTA

VERKKOYHTEYDEN KAUTTA

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Yksityisyyskäytännöt