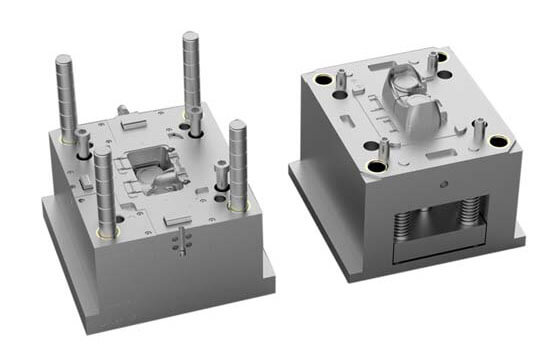

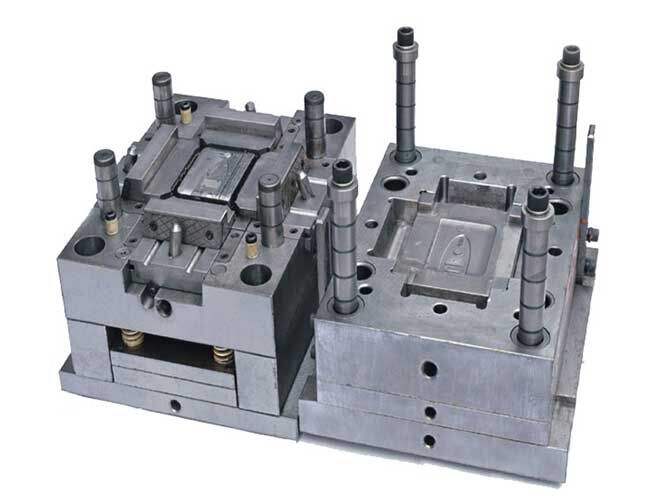

Os serviços de impressão de moldes por injeção da Qingdao Kaily utilizam tecnologias avançadas de fabricação aditiva para melhorar a funcionalidade do molde e a flexibilidade de design. A empresa utiliza sinterização a laser seletiva (SLS) e sinterização a laser direta de metal (DMLS) para produzir inserções de moldes com geometrias complexas, como canais de resfriamento conformais ou superfícies texturizadas, que a usinagem tradicional não consegue alcançar. Isso permite reduzir os tempos de ciclo e melhorar a qualidade das peças otimizando a distribuição de calor durante o moldado. As capacidades de impressão da Kaily também se estendem à prototipagem rápida de componentes de moldes, permitindo que os clientes validem designs antes da produção em larga escala. O uso de materiais de alto desempenho, como aço-ferramenta, alumínio e polímeros resistentes ao calor, garante que as peças impressas mantenham a estabilidade dimensional sob alta pressão e temperatura. Integrando impressão 3D com usinagem convencional, a empresa oferece soluções híbridas que equilibram precisão com eficiência de custo, tornando-a uma fornecedora de escolha para designs de moldes inovadores em indústrias que exigem recursos complexos ou iterações rápidas de design.

ONLINE

ONLINE

Direitos autorais © 2024 por Qingdao KAILY Electronic Technology Co., Ltd. Política de Privacidade