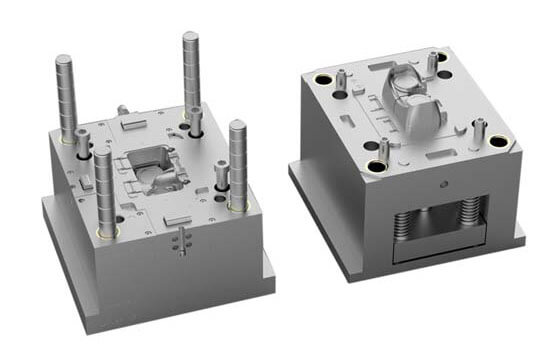

Ao comparar moldes de injeção e moldes de termoformagem, a Qingdao Kaily destaca as vantagens distintas da injeção para aplicações complexas e de alta precisão. Os moldes de injeção oferecem uma precisão dimensional superior (frequentemente dentro de ±0,05mm), tornando-os ideais para eletrônicos, peças automotivas e dispositivos médicos onde tolerâncias apertadas são críticas. O processo permite designs multi-cavidade, permitindo produção em alto volume com variação mínima das peças. Em contraste, os moldes de termoformagem são mais adequados para peças simples e maiores, como bandejas de embalagem, pois envolvem aquecimento e alongamento de folhas plásticas sobre um molde, o que limita detalhes e precisão. Os moldes de injeção da Kaily incluem componentes avançados como sistemas de corredor quente para reduzir o desperdício de material e resfriamento conforme para minimizar tempos de ciclo—vantagens geralmente não encontradas na termoformagem. Embora a termoformagem possa ser mais barata para produções de baixo volume, a injeção oferece economias de custo a longo prazo por meio de maior velocidade de produção e eficiência de material, tornando-a a escolha preferida dos clientes da Kaily em indústrias que demandam qualidade e repetibilidade.

ONLINE

ONLINE

Direitos autorais © 2024 por Qingdao KAILY Electronic Technology Co., Ltd. Política de Privacidade