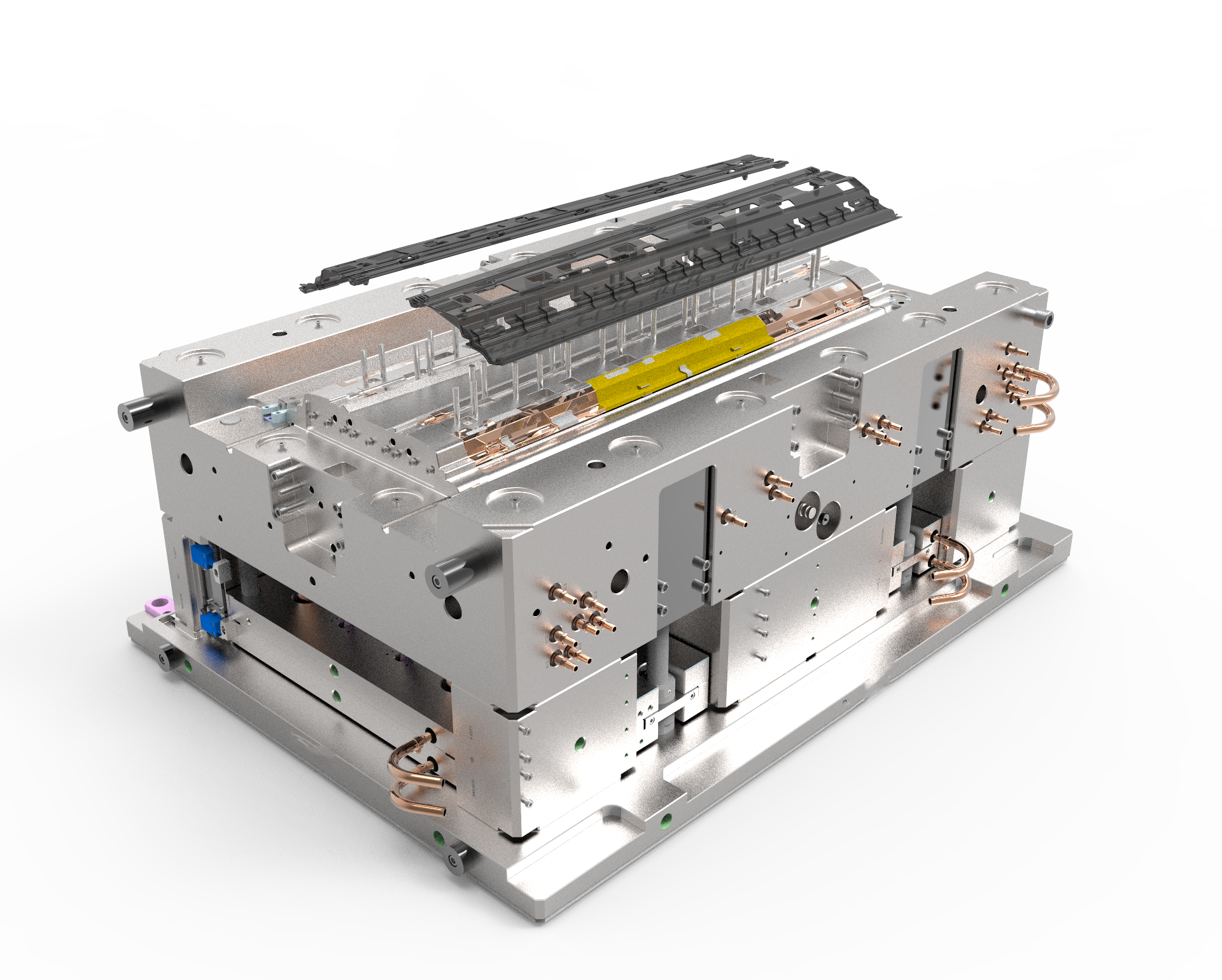

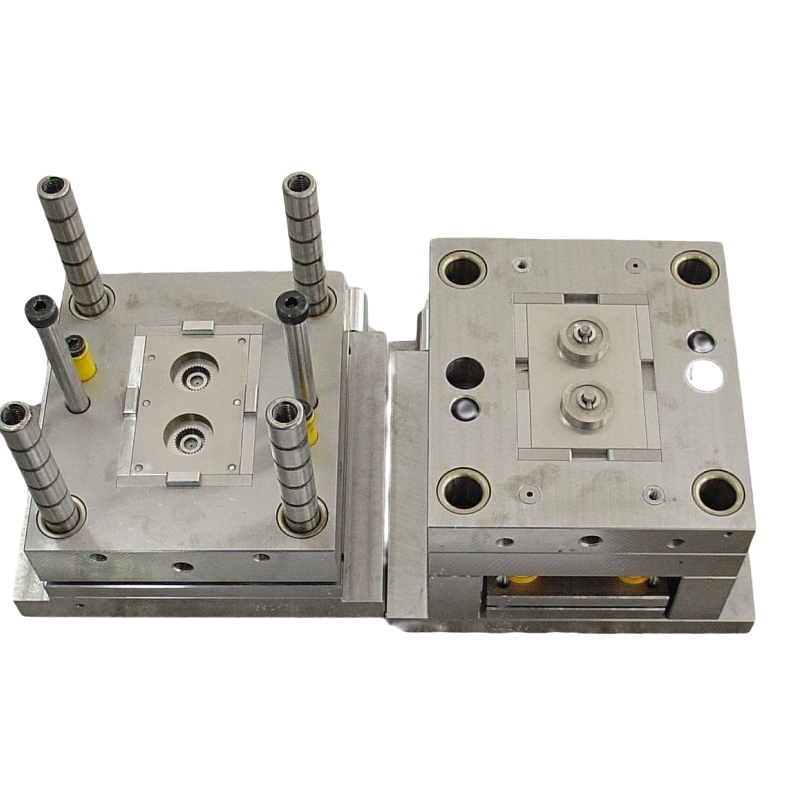

Qingdao Kaily Electronic Technology Co., Ltd. distinguishes between automotive and household injection molds by addressing their distinct technical requirements. Automotive molds prioritize durability and precision, often using high-tensile tool steels like H13 or S7 to withstand up to 500,000+ cycles for parts like bumper brackets. They incorporate advanced features such as conformal cooling channels (reducing cycle times by 30%) and multi-slide mechanisms for complex undercuts. In contrast, household molds focus on cost-effective efficiency, utilizing P20 steel for components like washing machine knobs. Kaily’s household designs emphasize quick-change color inserts and ergonomic surface texturing, while automotive molds undergo rigorous fatigue testing and comply with OEM standards like ISO 16949. Both types leverage the company’s modular design approach, but automotive molds feature tighter tolerances (±0.03mm) versus household molds’ ±0.1mm, reflecting their respective industry demands.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy