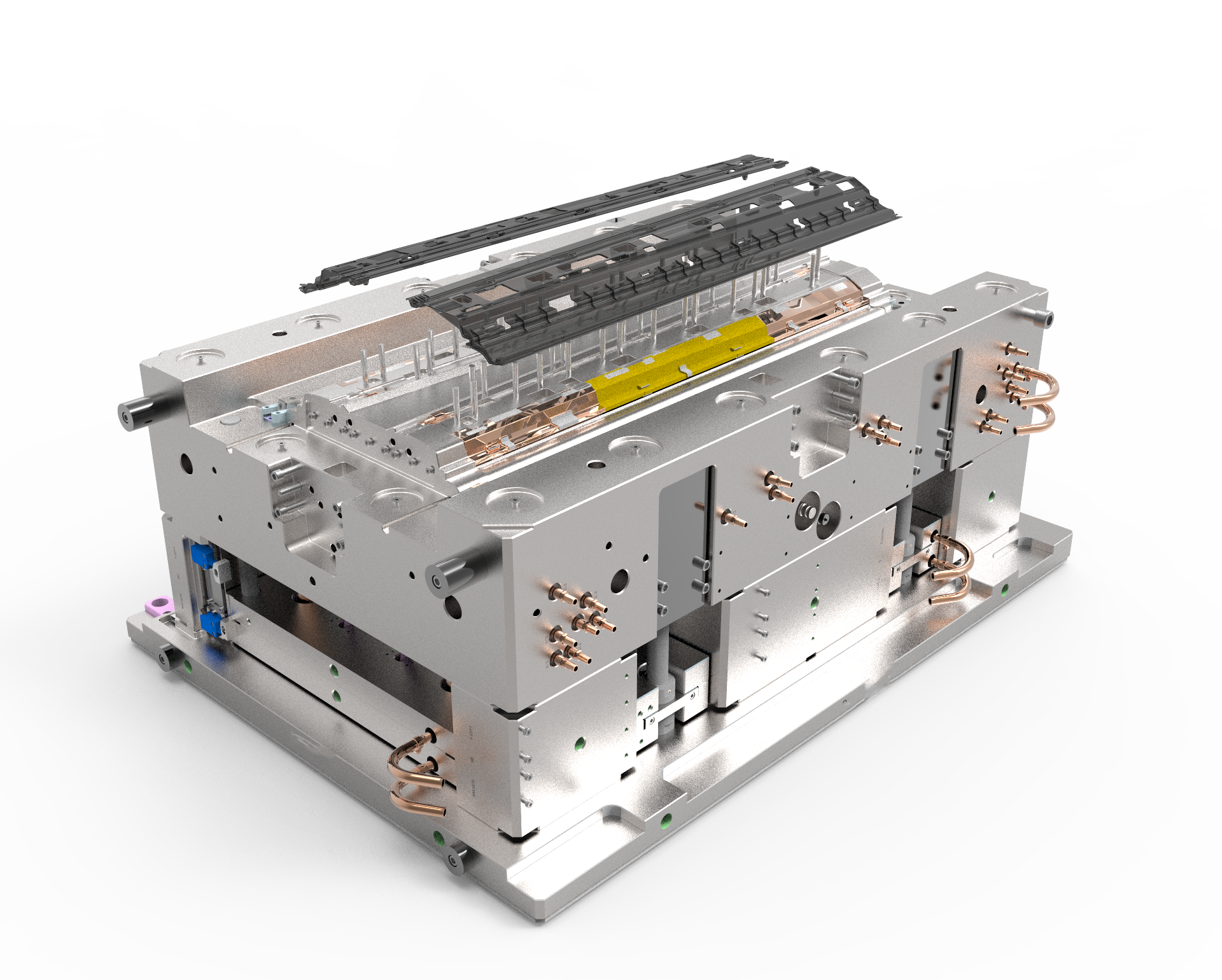

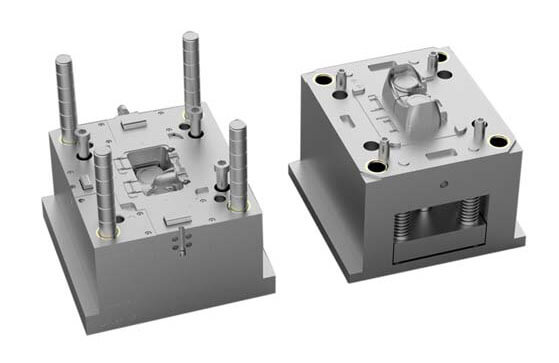

The automotive interior parts injection molds produced in the company are made to comply with high standards set within the automotive industry. We aim at producing such products which will not only comply with the functional expectations but also be appealing to the vehicle interiors. Molds are designed to high standards to ensure that when being used in automotive applications they will perform as expected without fail. We make use of the modern manufacturing processes and materials and hence by the order of our clients we will be able to make modern injection molds which are used in several countries.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy