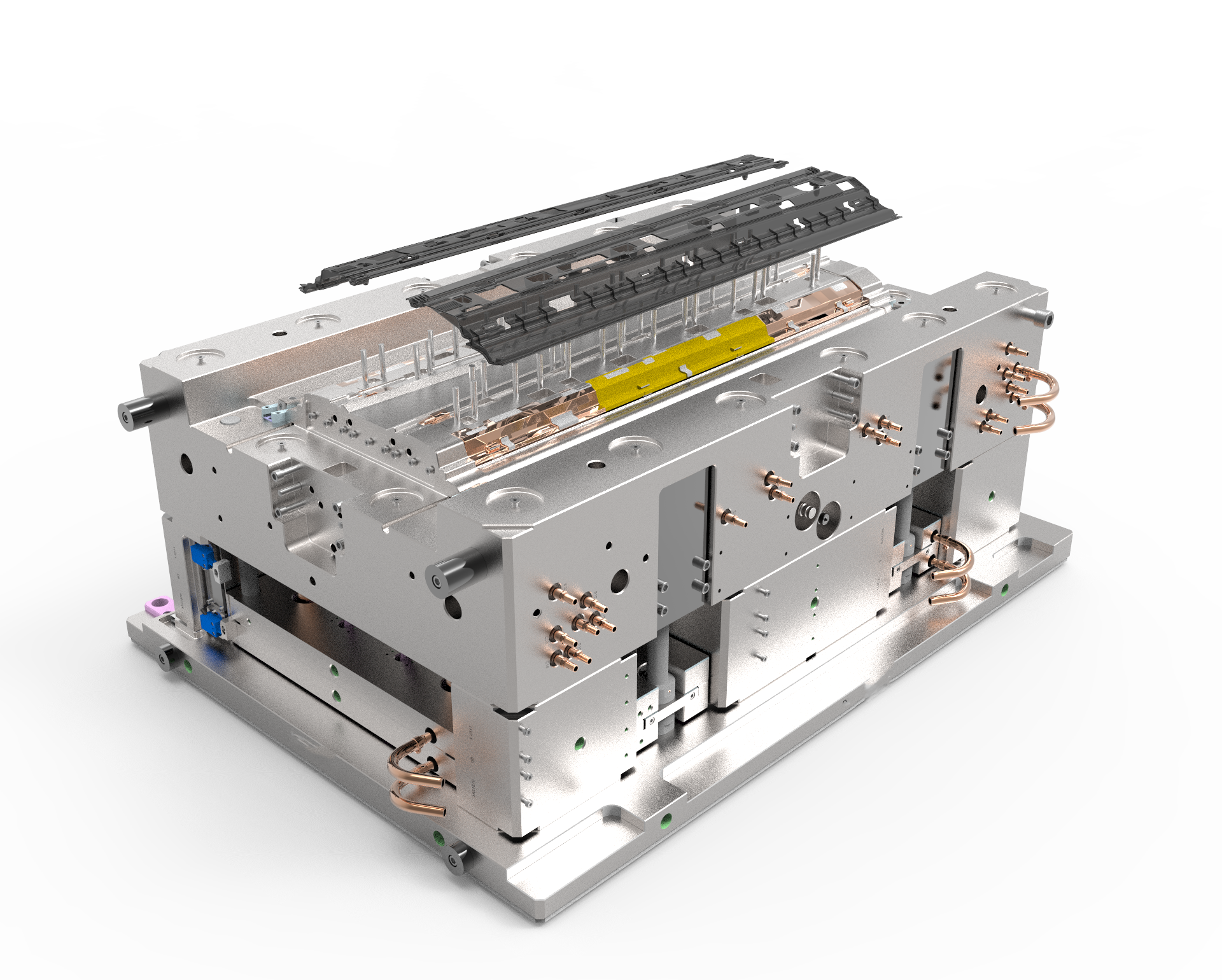

Durable electronic molds are built with corrosion-resistant steel and undergo nickel-plating treatments, ideal for humid or high-temperature environments (e.g., outdoor electronics, industrial controls). Reinforced ejection systems and stress-analyzed structures prevent wear and tear, ensuring long-term reliability for components like connectors, enclosures, and terminal blocks.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy