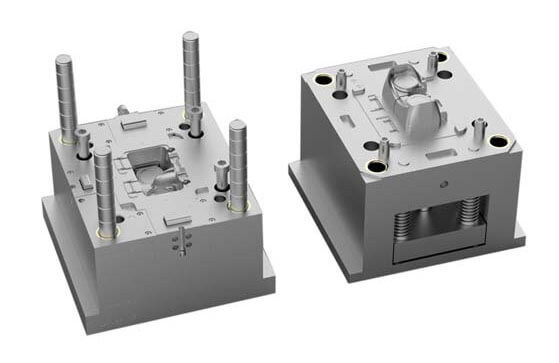

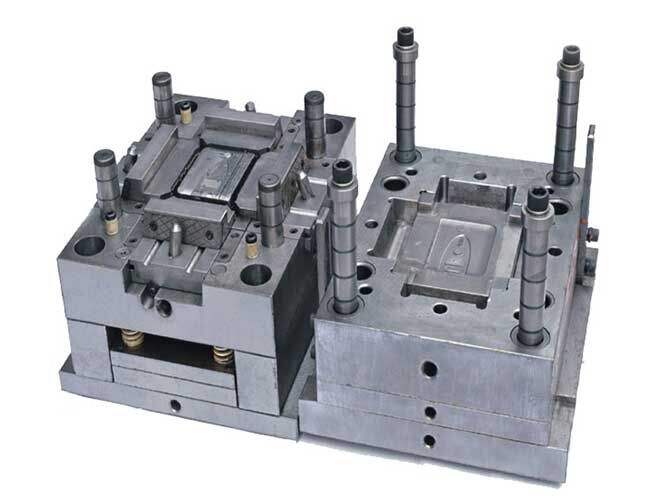

Precision is core to our mold design, achieved through 5-axis CNC machining and laser scanning for ±0.01mm tolerance. We use advanced CAD/CAM software to model complex geometries, ensuring seamless integration of inserts, sliders, and multi-cavity layouts. Rigorous dimensional inspections (CMM testing) guarantee parts meet exact specifications for industries like electronics, medical devices, and automotive.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy