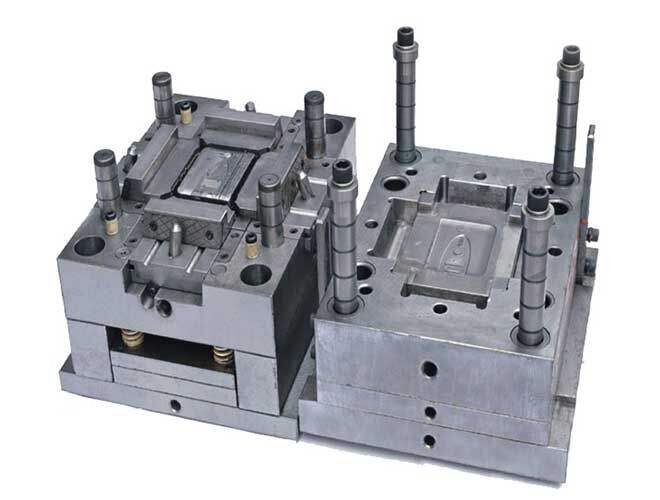

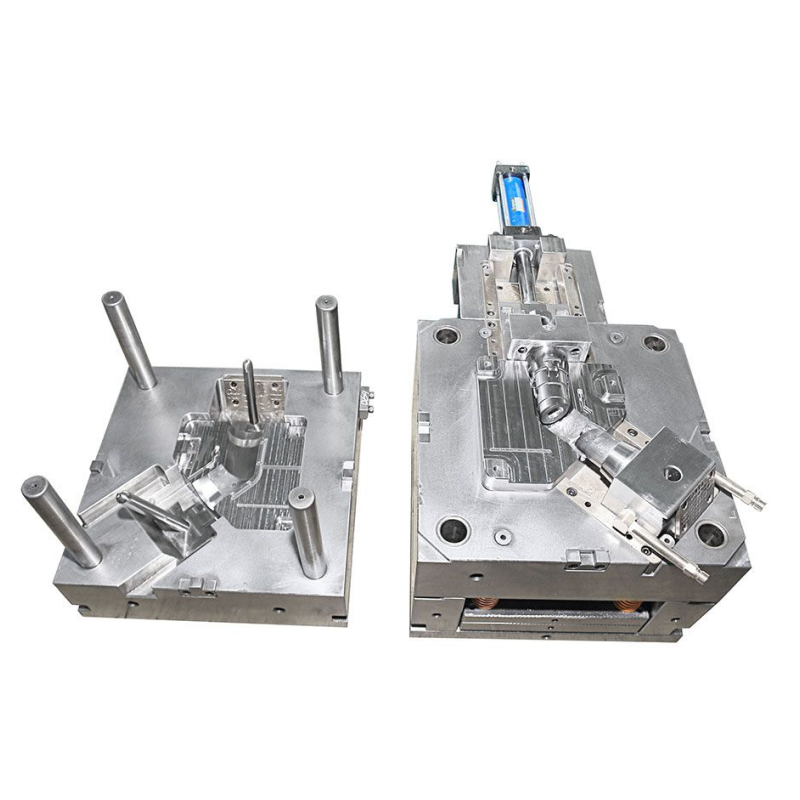

Qingdao KAILY Electronic Technology Co., Ltd has gained expertise in efficient plastic mold production which is needed in different sectors. The centers of our professional activity are interconnected: starting from mold’s designing and ending with assembling of the ready product. We are able to meet deliveries using sophisticated technology as well as well trained personnel for such production of the Molds. Quality assurance means not only improved functionality of the produced items, but also decreased amount of waste and expenses, thus strengthening new company’s clients around the world.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy