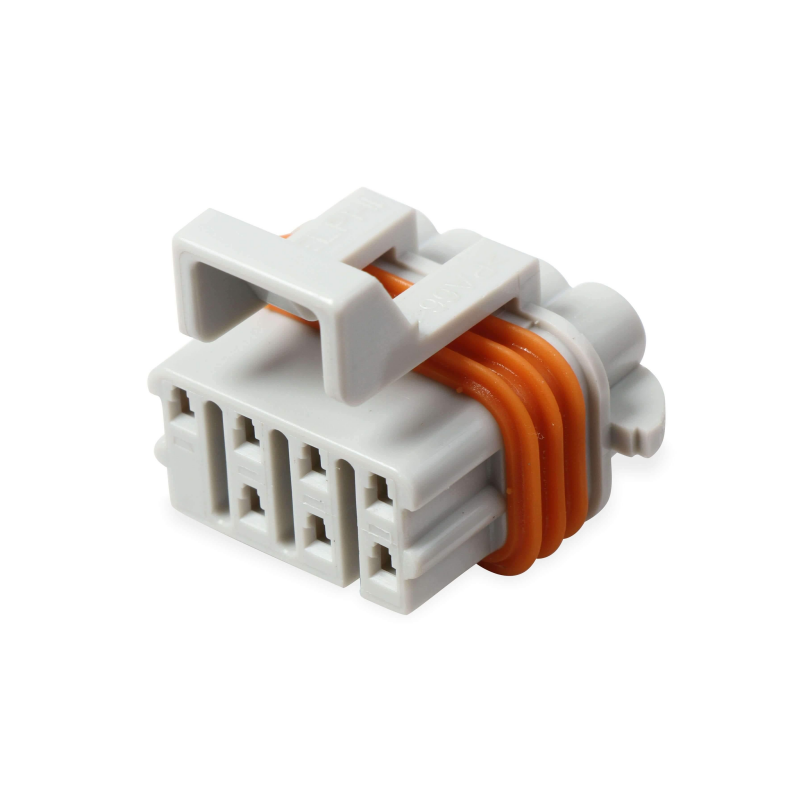

Qingdao Kaily specializes in electronic component molding, addressing the sector’s strict requirements for precision, reliability, and miniaturization. The company’s molds for electronic components feature: 1) micro - gating systems to minimize material waste in small parts; 2) anti - static mold surfaces to protect sensitive circuitry; 3) high - temperature resistance for lead - free soldering compatibility. Kaily’s expertise extends to overmolding applications, where it creates multi - material components like cable connectors with integrated strain relief. For semiconductor packaging, the company uses hermetically sealed molds to prevent contamination, while its insert molding capabilities allow for seamless integration of metal contacts into plastic housings. All electronic component molds undergo rigorous testing for flash prevention, gate vestige control, and dimensional stability across temperature ranges. By combining cleanroom - compatible manufacturing with advanced design software, Kaily ensures its electronic component molds meet the exacting standards of OEMs and contract manufacturers worldwide.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy