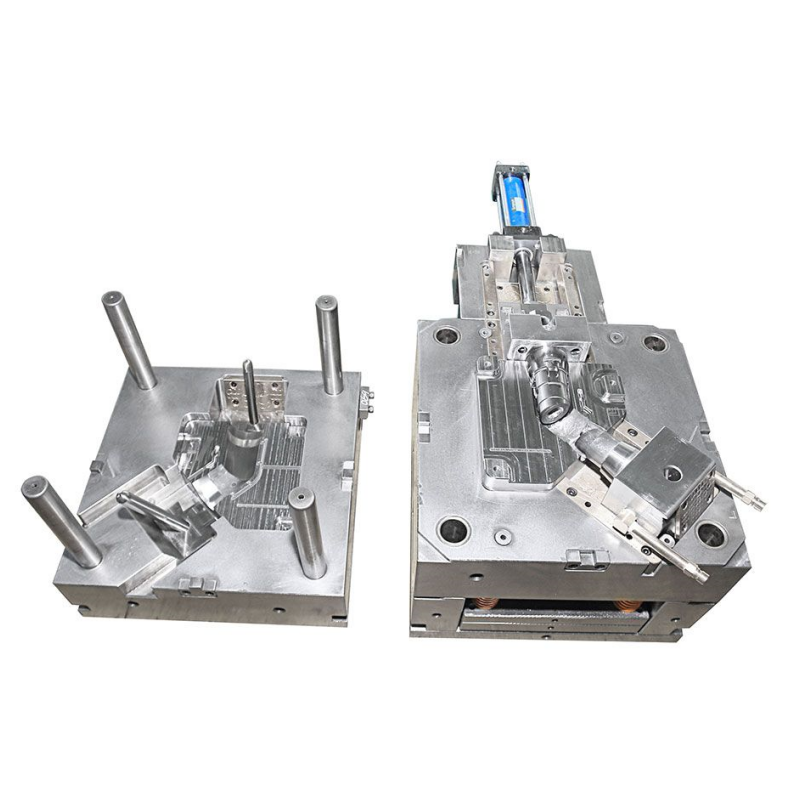

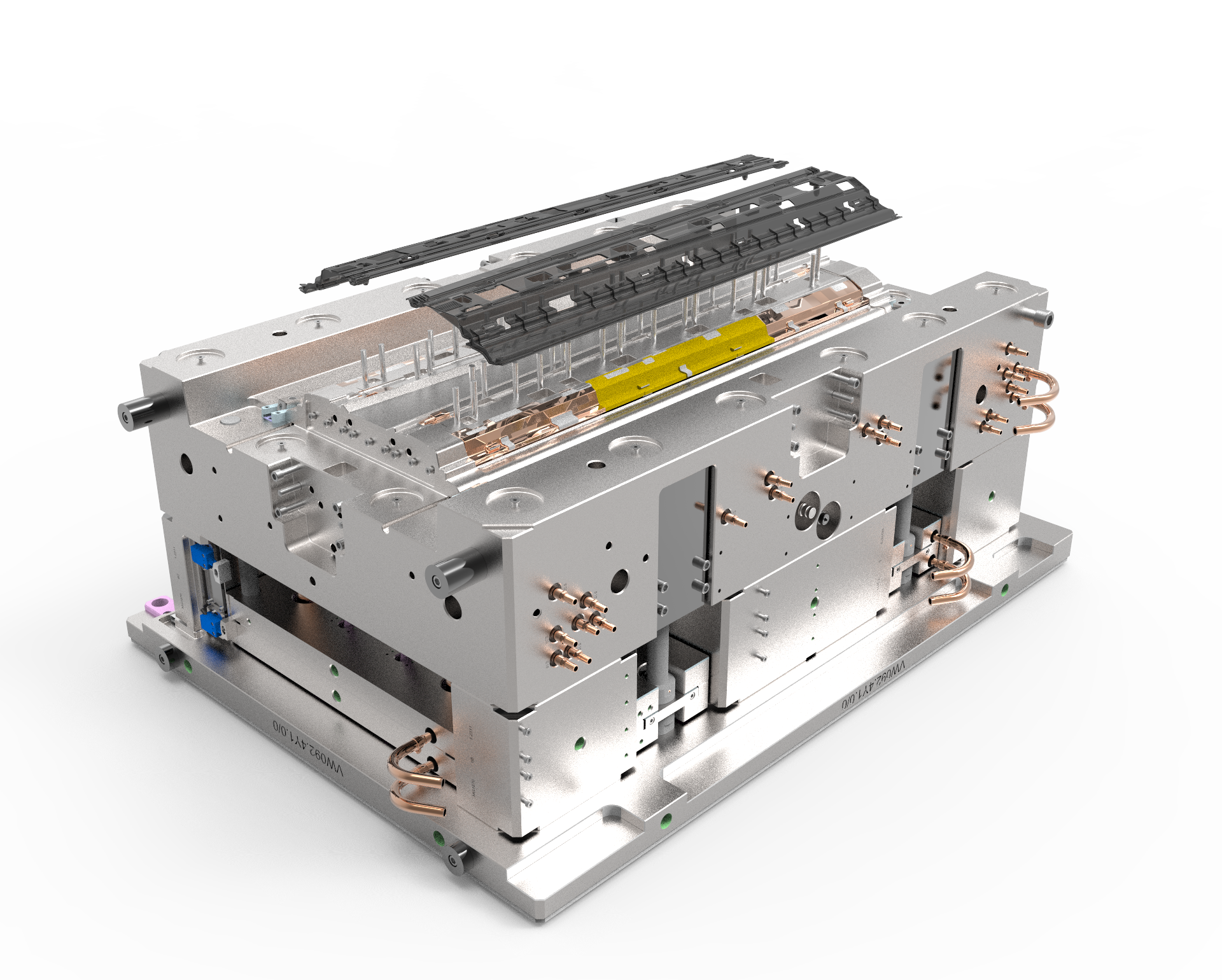

Qingdao Kaily’s high-performance plastic injection molds are engineered for demanding applications requiring extreme durability and precision. These molds utilize premium materials like powder metallurgy steels (e.g., V4E) and ceramic-reinforced composites, enabling operation at temperatures up to 400°C and pressures exceeding 2,000 bar. Key features include: 1) hot runner systems with melt temperature control to 0.5°C accuracy; 2) DLC-coated cavities for 10x wear resistance; 3) multi-layer cooling channels for uniform heat dissipation. Used in aerospace (e.g., fuel system components) and medical (sterilizable implants), these molds undergo rigorous validation, including 10,000-cycle stress testing. Kaily’s high-performance solutions reduce production defects by 85% compared to standard molds, making them ideal for mission-critical applications.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy