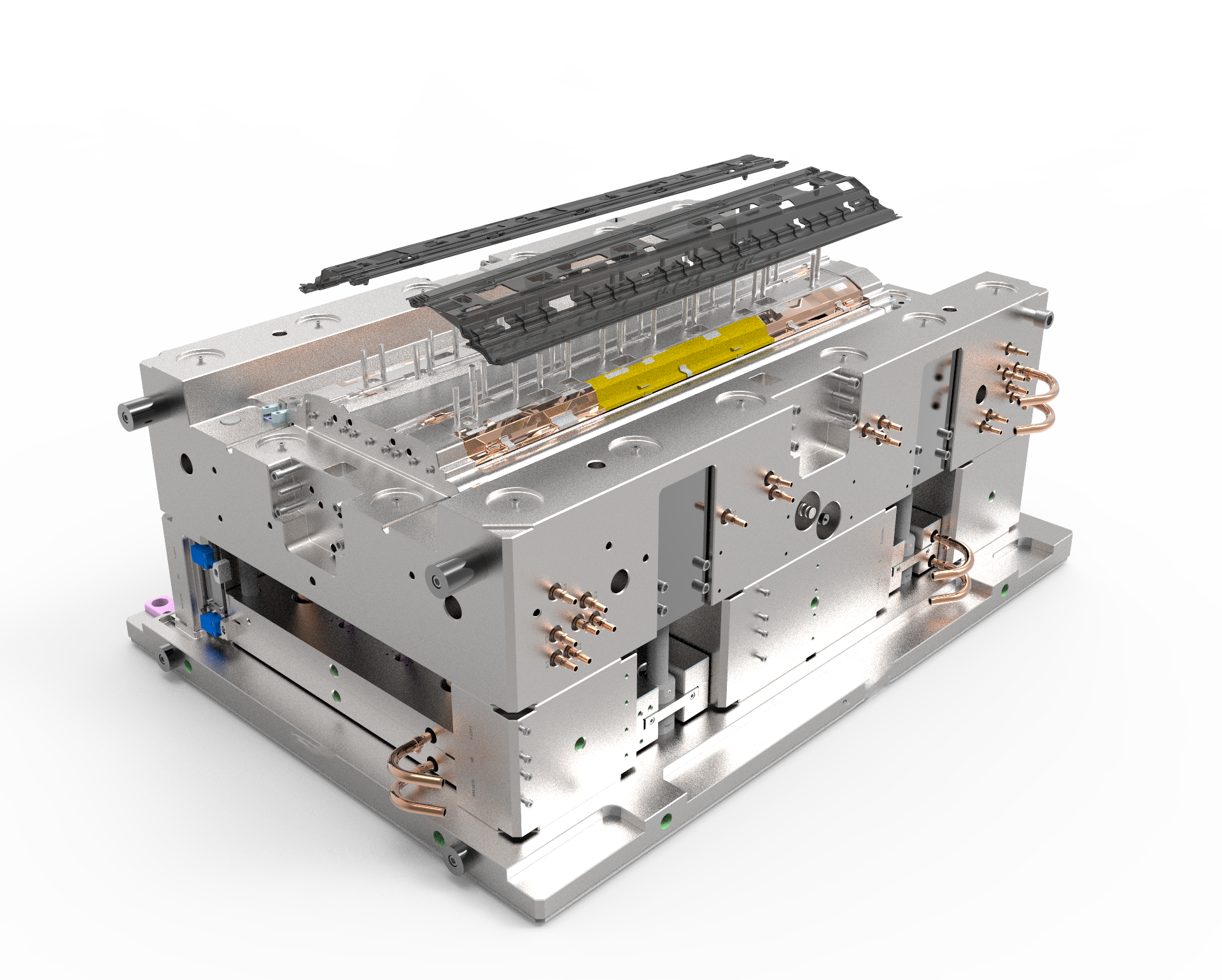

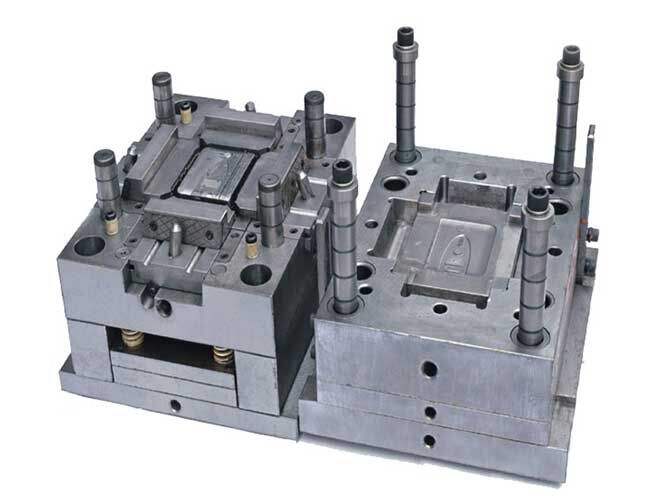

The activity of making plastic molds is one that demands an understanding of materials, manufacturing process, molding and the product itself. Such initiatives exist at Qingdao KAILY Electronic Technology Co., Ltd. where we go beyond designing molds to perfecting their manufacturing processes. As part of the necessary processes, the entire design team remains in contact with the clients to achieve high quality designs that meet the prescribed specifications and requirements. Below are some of the benefits which your firm will enjoy by engaging our services such as advanced technology, extraordinary design and engineering techniques which enable us to design and fabricate molds that improve the quality of the product and avoiding needless production overheads.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy