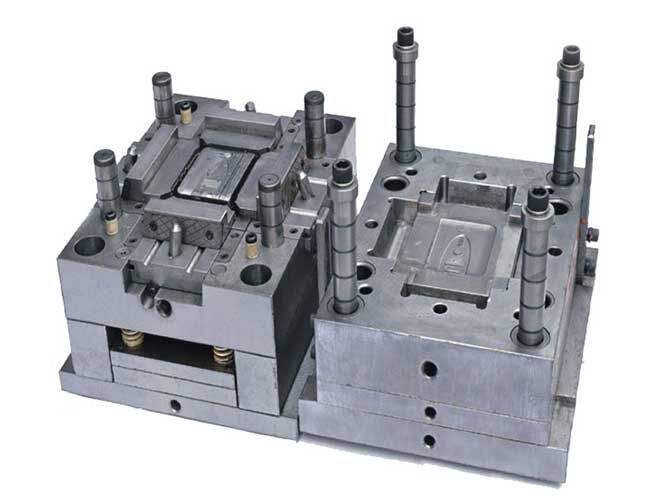

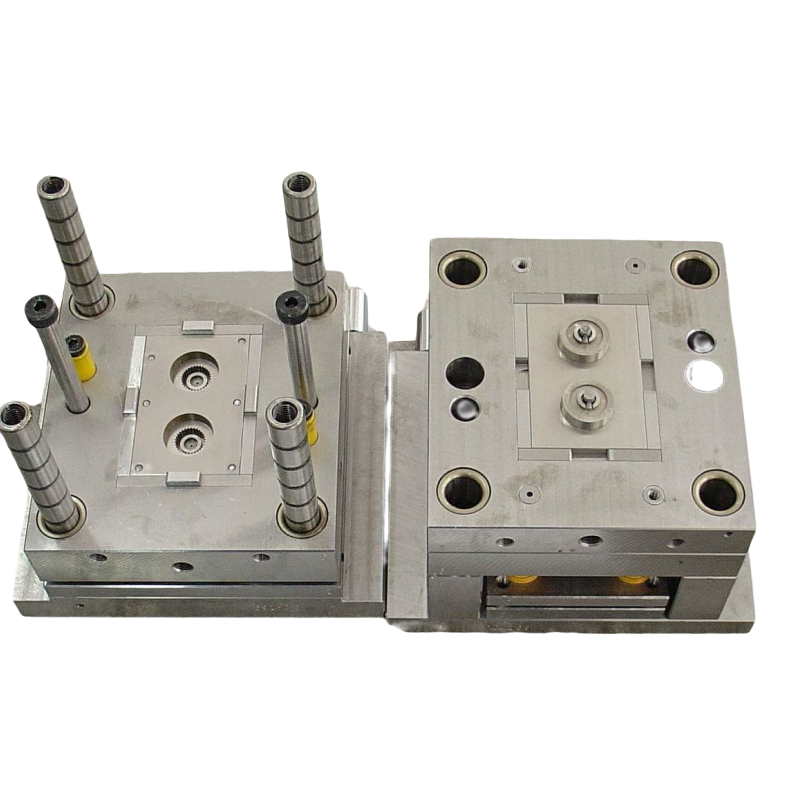

Our company specializes in the production of plastic molds for lighting fixtures which correspond to the actual trends and requirements of the market. We know that an effective lighting structure should not only ‘look good’ but also need to be long lasting and functional. Such absolute qualities are guaranteed by production of the molds from modern high-quality materials. We try to be fast and precise in our work to keep production cycles short while delivering on the expected standards. We aim at innovation as a major concern for any business and therefore provide the trends of the times in the form of molds suitable to your marketing goals.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy