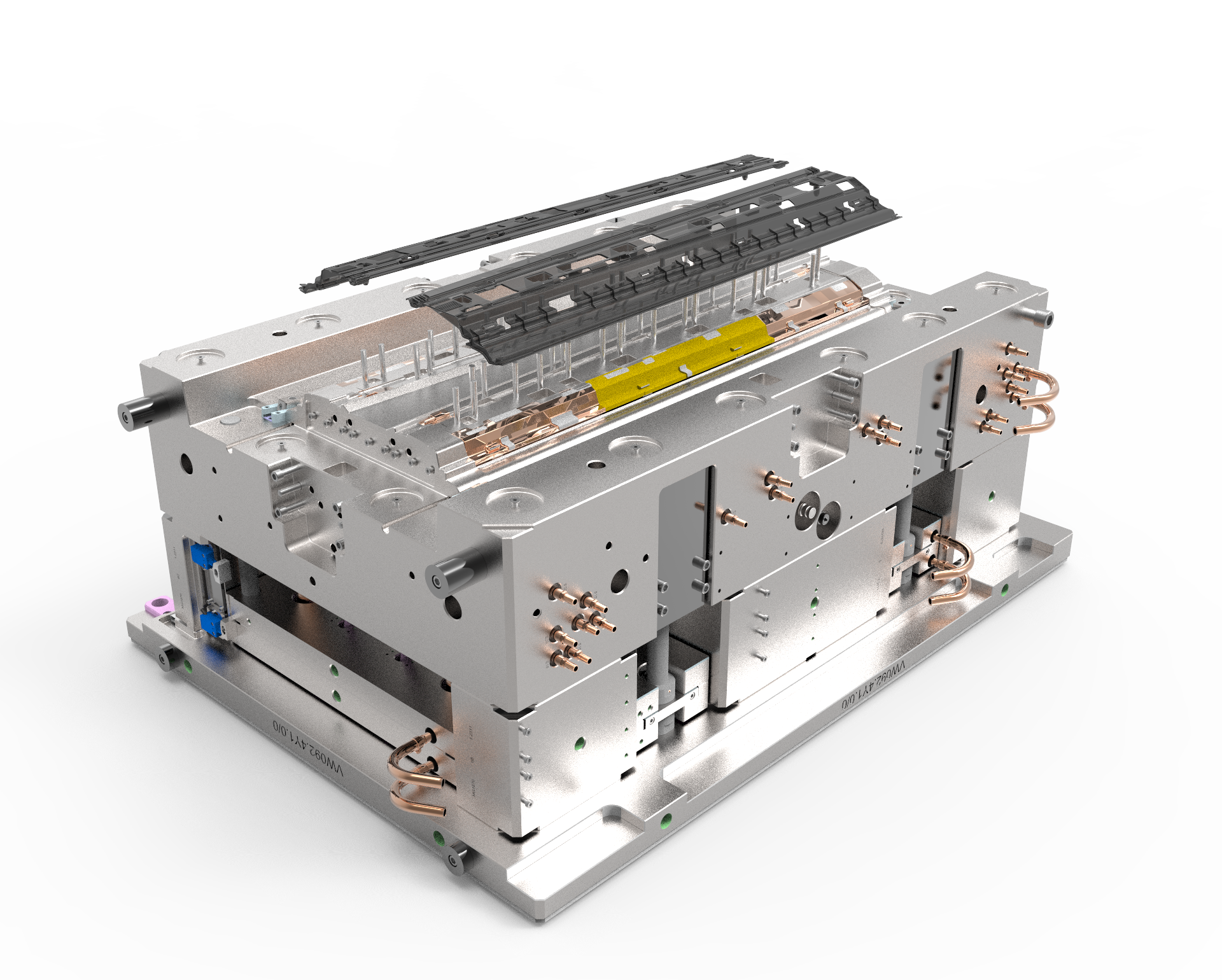

Qingdao Kaily’s approach to injection mold material selection is rooted in application - specific engineering and performance optimization. The company’s material experts consider factors such as: 1) production volume (e.g., P20 steel for low - volume runs vs. H13 for millions of cycles); 2) plastic type (e.g., corrosion - resistant stainless steel for PVC compounds); 3) part geometry (e.g., beryllium copper for thin - walled parts requiring rapid cooling); 4) surface finish requirements (e.g., polished S136 steel for optical components). For high - temperature applications, Kaily uses heat - resistant alloys like tungsten carbide, while for medical devices, it employs FDA - compliant stainless steels. The company also evaluates cost - performance ratios, offering budget - friendly options like aluminum for prototypes and premium tool steels for high - volume production. By leveraging partnerships with global material suppliers, Kaily ensures consistent quality and availability, while its in - house heat treatment capabilities allow for customized material properties to meet unique project needs.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy