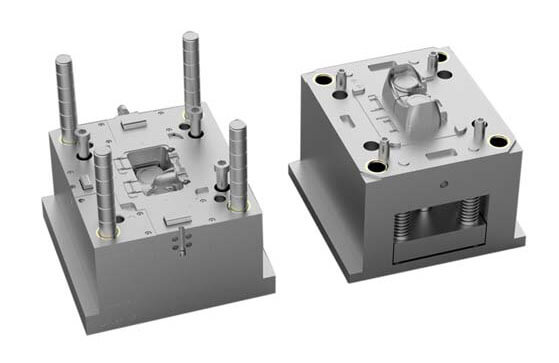

Qingdao KAILY Electronic Technology Co. Ltd knows that the assembly of electronic components is a systematic operation that needs both precision and stability. Injection molding tools that stand the expectations of the nature of this industry are what we design. Our molds provide quality and durable solutions thus increasing production speed. With our dedication to innovation and quality, we provide molds that meet customer expectations as clearly defined thus commanding a lot of preference in the market for businesses seeking injection molding services.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy