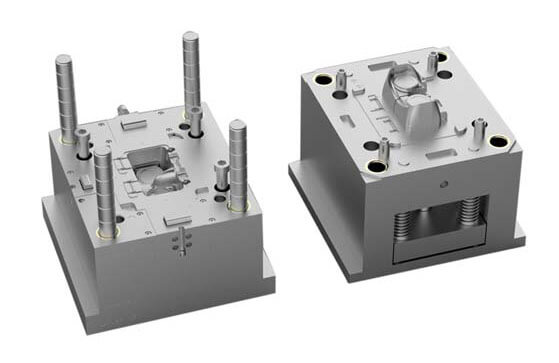

Qingdao Kaily designs household appliance injection molds to balance durability, production efficiency, and ergonomic design. These molds are crafted from high - tensile tool steels (e.g., P20 or H13) to withstand the high pressures of molding large parts like refrigerator door panels or washing machine components. The company incorporates features such as multi - slide mechanisms for complex geometries (e.g., handles with undercuts) and hot runner systems to reduce material waste in bulk production. Cooling systems are optimized for rapid cycle times, with spiral channels in cylindrical parts like kettle bodies to ensure uniform cooling. Kaily also addresses industry-specific challenges, such as UV resistance for outdoor appliance parts or flame retardancy for kitchen components, by selecting appropriate mold materials and surface treatments. Their household appliance molds undergo rigorous fatigue testing to ensure they maintain precision over millions of cycles, making them a reliable choice for major appliance manufacturers seeking consistent quality and long - term value.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy