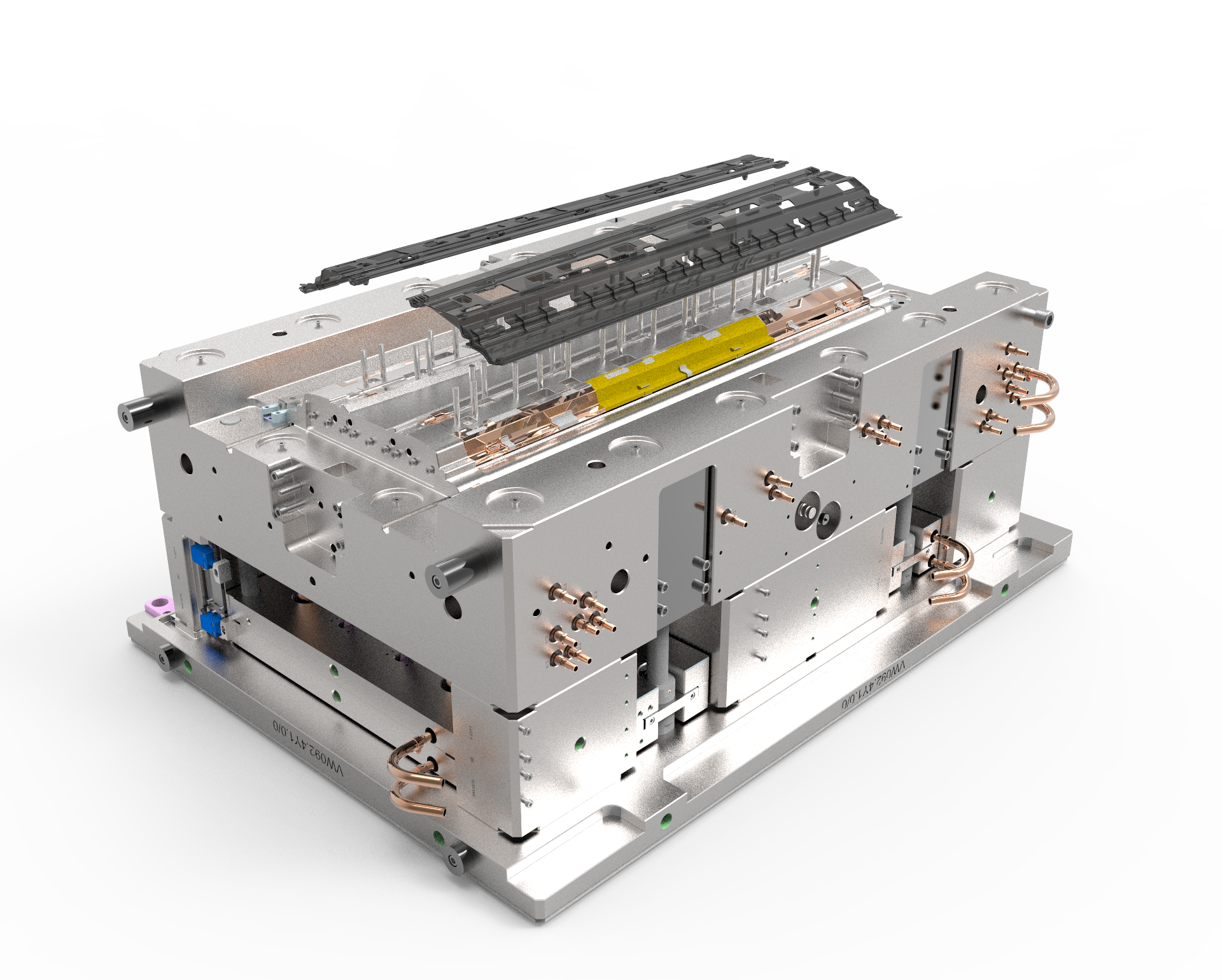

Injection molding is an important aspect of manufacturing electronic components that require precision and toughness. Qingdao KAILY Electronic Technology Co., Ltd. makes high-quality injection molds for electronics. Our molds are designed to uphold the complexities of electronic designs and functions to maximize their performance and strength. Our vast experience coupled with continuous improvement and development helps us in delivering what our customers want at reasonable rates.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy