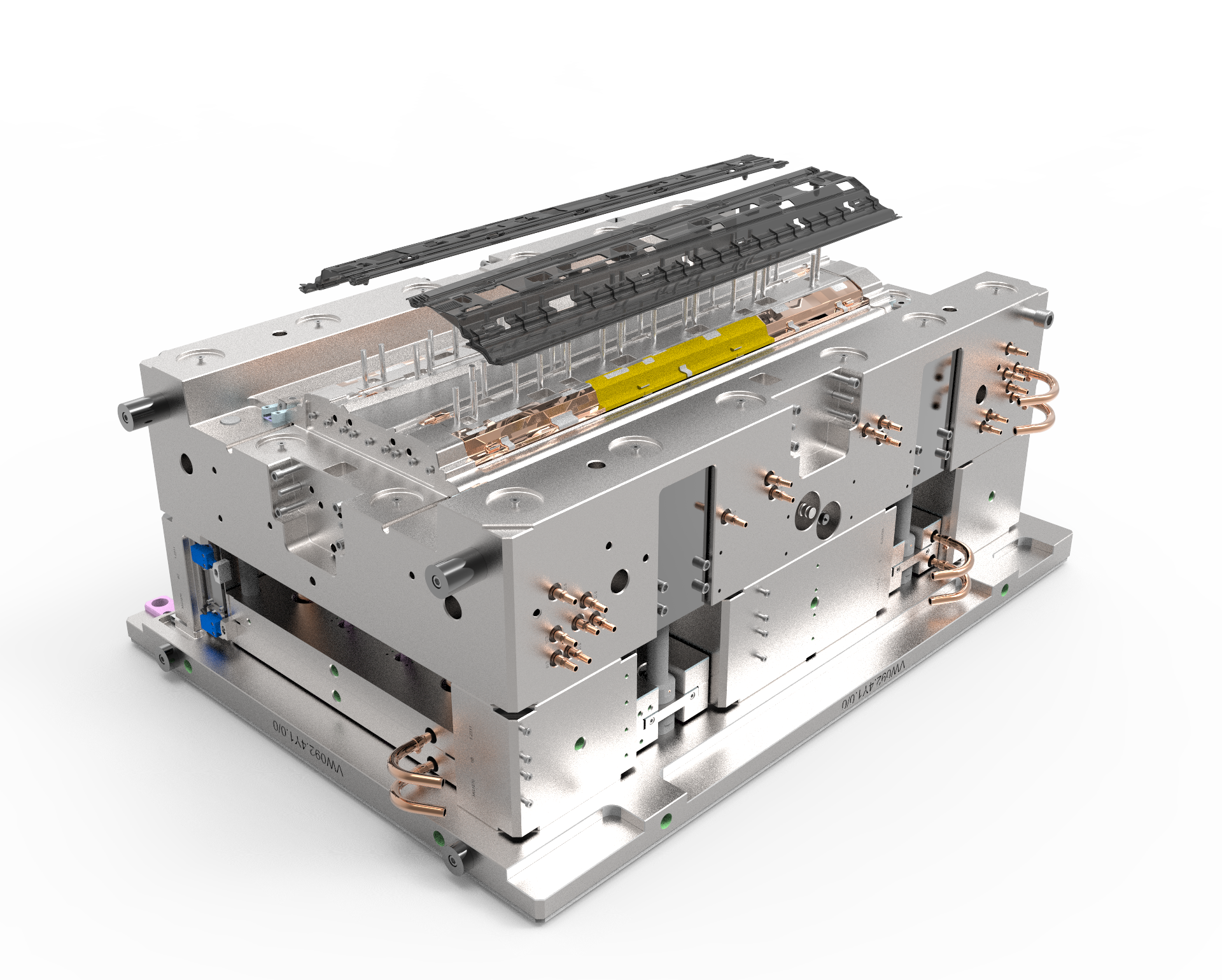

Plastic molds differ from die casting in material flexibility and cost-effectiveness. Our plastic molds excel in producing lightweight, intricate parts with precise details, suitable for electronics and automotive components. Unlike die casting, which suits high-melting-point metals, our plastic molds offer lower production costs for complex designs, ideal for mass production with customizable finishes and reduced material waste.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy