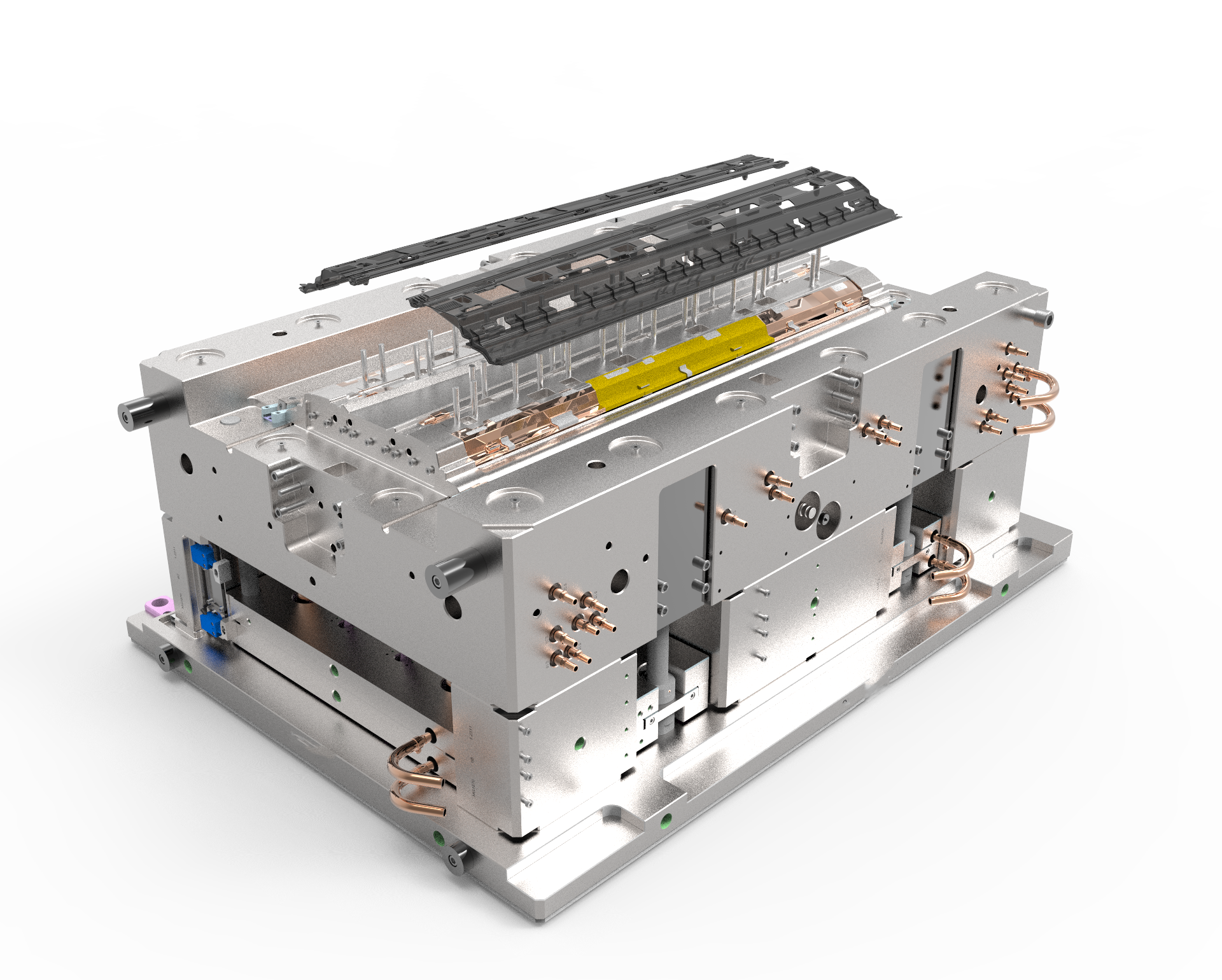

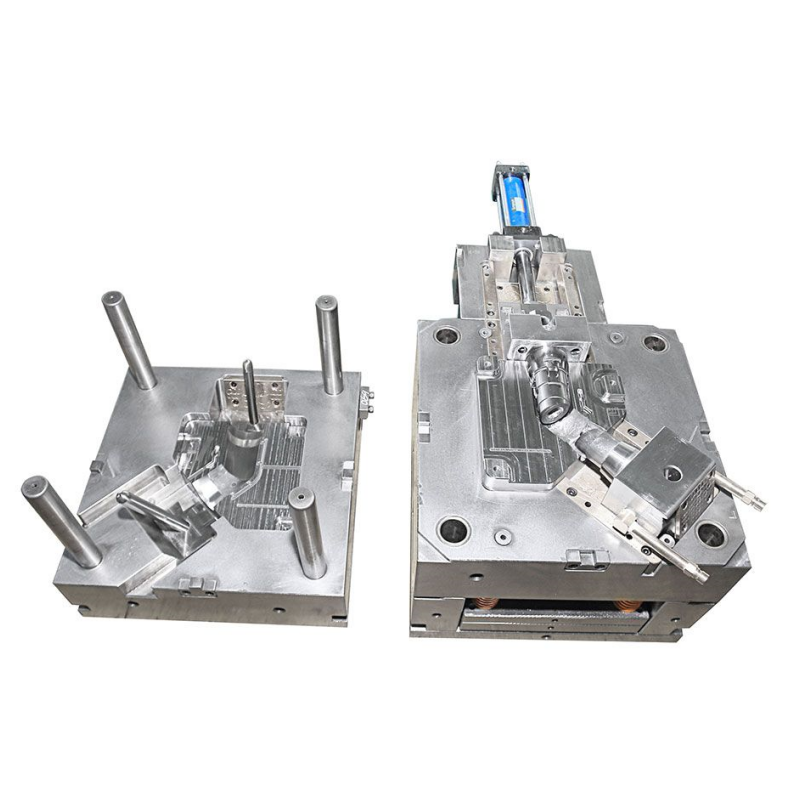

Plastic injection mold is the process in which a heated material is injected within a removable assembly to achieve specified and intricate patterns. This procedure is ideal for repetition of functionality given the quality and consistency of the product. This process starts by building a mold, where the heated plastic is poured, cooled and hardened in the specific form of the mold. So efficient, so economical, produces very detailed and tight toleranced components and is able to be deployed into many different applications making it a very popular technique.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy