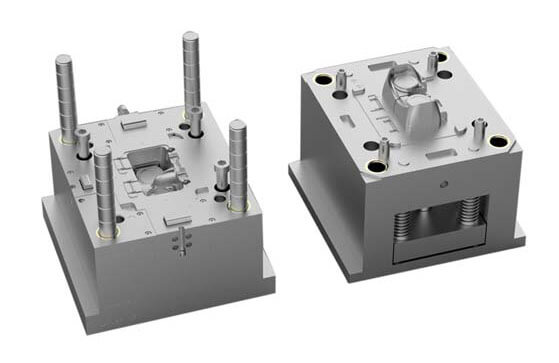

Engine component molds must withstand extreme heat (up to 250°C) and chemical corrosion, so we use premium H13 tool steel with ceramic coatings. These molds produce intake manifolds, valve covers, and turbocharger parts with tight tolerances, ensuring optimal heat dissipation and mechanical strength. Our solutions meet stringent automotive performance and emission standards.

ONLINE

ONLINE

Copyright © 2024 by Qingdao KAILY Electronic Technology Co., Ltd. Privacy policy